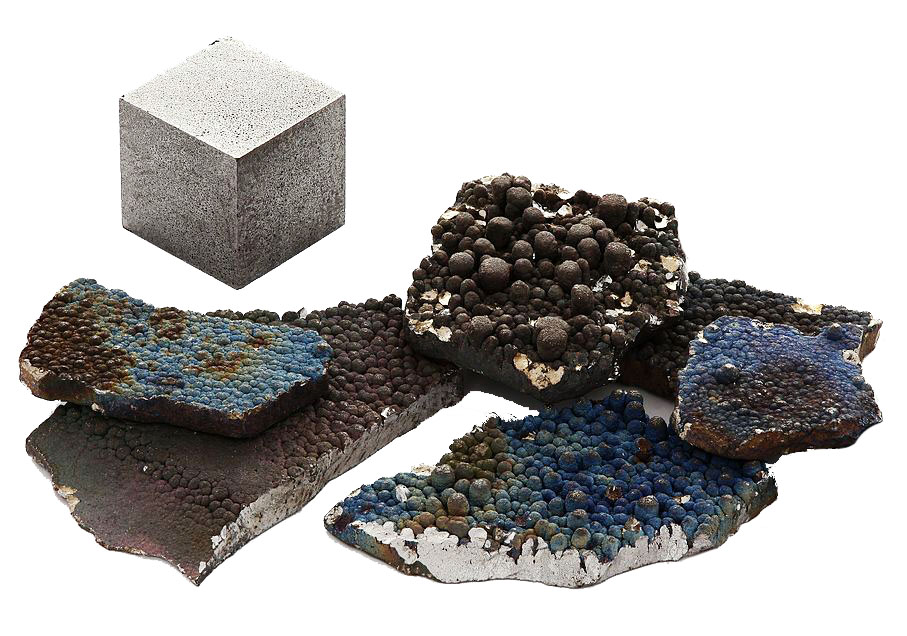

Characteristics of Manganese

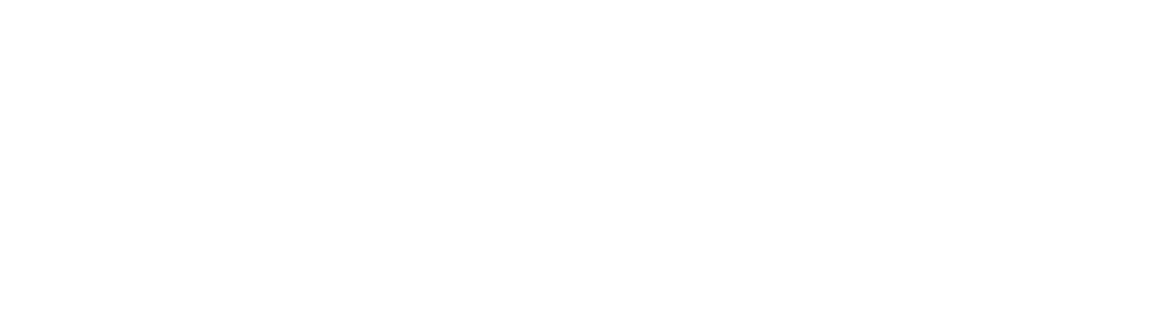

Manganese is a hard, brittle grayish-white metal with the chemical symbol Mn. It does not occur in nature as the free element, but combines with other elements to form oxides, hydroxides, silicates and carbonate minerals. There are over 460 known minerals containing manganese. The average manganese content of the Earth's crust is about 950 mg/kg (0.095 percent). The most common ore minerals are manganese oxides, including pyrolusite (MnO2), which often occurs as steely-grey black crusts and radiating fibrous aggregates in sedimentary and hydrothermally-altered rocks, as well as secondary accumulations. When extracted as the pure metal, manganese has properties that are similar to iron, although it is not magnetic. Some of the important manganese-enriched minerals reported in Virginia are listed in Table 1.

| Mineral Name | Chemical Formula | Specific Gravity | Mn % |

|---|---|---|---|

| Pyrolusite | MnO2 | 5.0 gm/cc | 63.19 |

| Cryptomelane | KMn8O16 | 4.17-4.33 gm/cc | 59.83 |

| Psilomelane | Ba(Mn2+)(Mn4+)8O16(OH)4 or (Ba,H2O)Mn5O10 | 4.4-4.7 gm/cc | 46.56 |

| Manganite | MnOOH | 4.3-4.4 gm/cc | 62.47 |

| Rhodochrosite | MnCO3 | 3.3-3.6 gm/cc | 47.79 |

| Rhodonite | CaMn4Si5O15 | 3.57-3.76 gm/cc | 38.29 |

| Spessartine | Mn3Al2(SiO4)3 | 4.12-4.32 gm/cc | 33.29 |

Table 1: Minerals containing the element Manganese

Steel railroads require manganese for manufacturing

Uses of Manganese

Manganese is considered a "critical mineral" in domestic metallurgical applications that serve aerospace, defense, energy, and transportation technologies (Fortier and others, 2018). Manganese is a crucial ingredient in the production of steel by virtue of its sulfur-fixing, deoxidizing, and alloying properties. Steel-making accounts for 85 - 90 percent of the total domestic demand for manganese (U.S. Geological Survey, 2020). Manganese ferroalloys, consisting of various grades of ferromanganese and silicomanganese are used as a key ingredient for steelmaking. Leading end use products are used in construction, machinery, and transportation. Manganese is also important in the production of aluminum alloys and cast iron. Manganese dioxide is strategically significant for the production of dry-cell batteries. Non-metallurgical uses of manganese include: plant fertilizers, animal feed, and colorants for brick. In 2019, the value of domestic consumption, estimated from foreign trade data on a manganese-content basis, was about $1.2 billion (USGS, 2020).

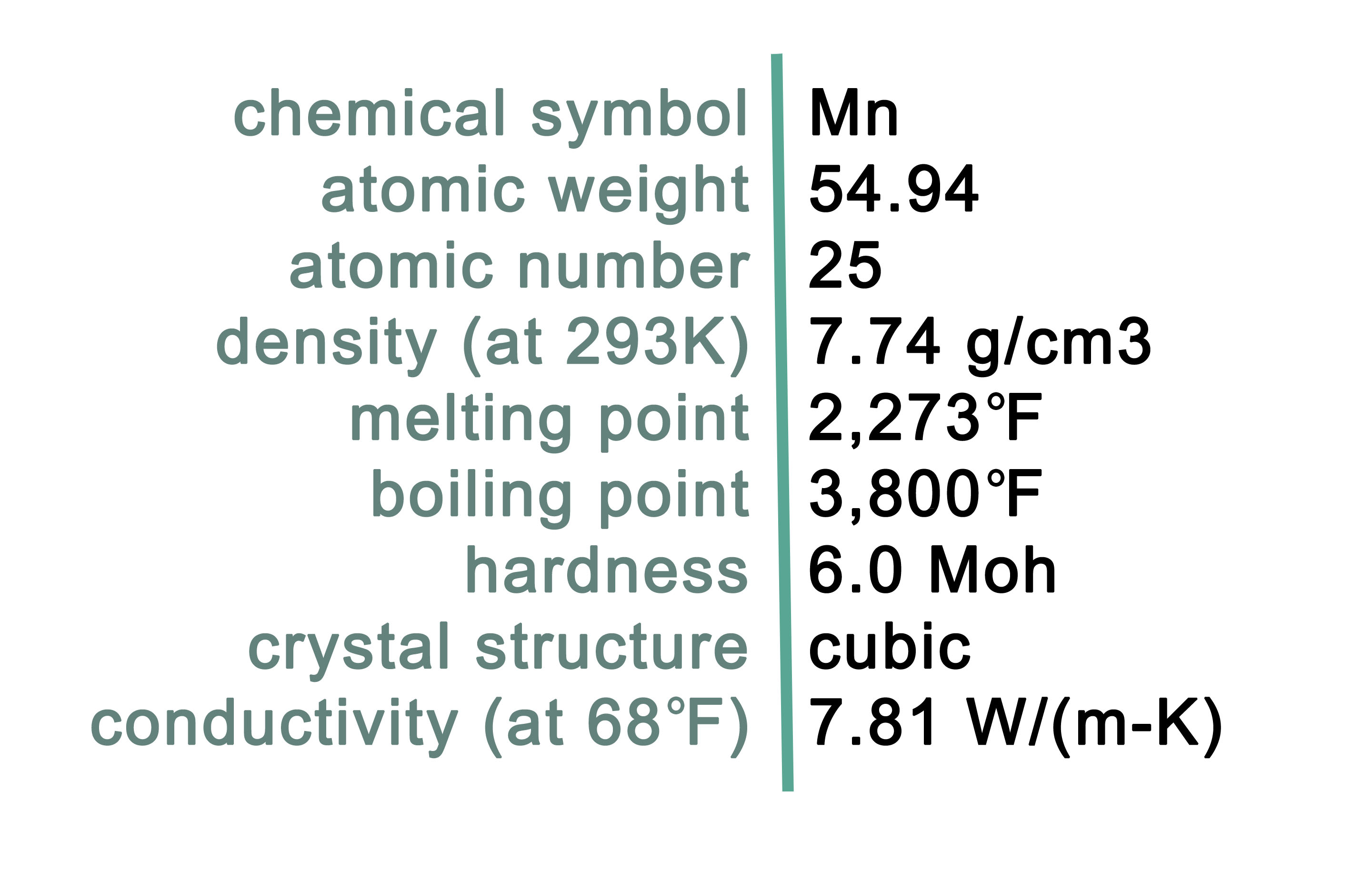

Ferromanganese nodules litter the seafloor.

Courtesy of James R. Hein, U.S. Geological Survey.

Manganese Geology

Manganese minerals are relatively common in the Earth's crust. The greatest abundance of manganese is in the form of ferromanganese nodules and crusts along the ocean floor. Marine chemical processes and microorganisms capture dissolved manganese in seawater, which is precipitated on the ocean floor. Although seafloor deposits constitute an enormous potential resource, the economic feasibility of exploration and recovery is not currently viable.

The highest concentrations of obtainable manganese may be found in very old (some are 2.5 billion years old) marine sedimentary rocks that are now exposed on land. Initially, the manganese becomes concentrated in marine environments. On continental margins, manganese may precipitate with iron, forming layers of iron- and manganese-rich sediment as oxidation and acidity of the water fluctuate, forming banded iron formations. Once such sedimentary rocks have been uplifted or transported to a terrestrial environment, chemical weathering may result in supergene enrichment and the formation of residual and replacement manganese deposits.

| Mineral System | Deposit Type | Geologic Provinces |

|---|---|---|

| Chemical Weathering | Residual Mn with clays, replacement, and supergene enrichment |

Valley and Ridge, Piedmont |

| Marine Chemocline | Mn-Fe chemical sediments | Valley and Ridge, Piedmont |

| Basin Brine | Mn-silicate veins (modified by structural and metamorphic processes) | Blue Ridge |

| Volcanogenic Seafloor | Mn Oxide nodules, crusts | Offshore marine |

Table 2: Prospective manganese mineral systems, deposit types (Hofstra and Kreiner, 2020), and geologic provinces in Virginia

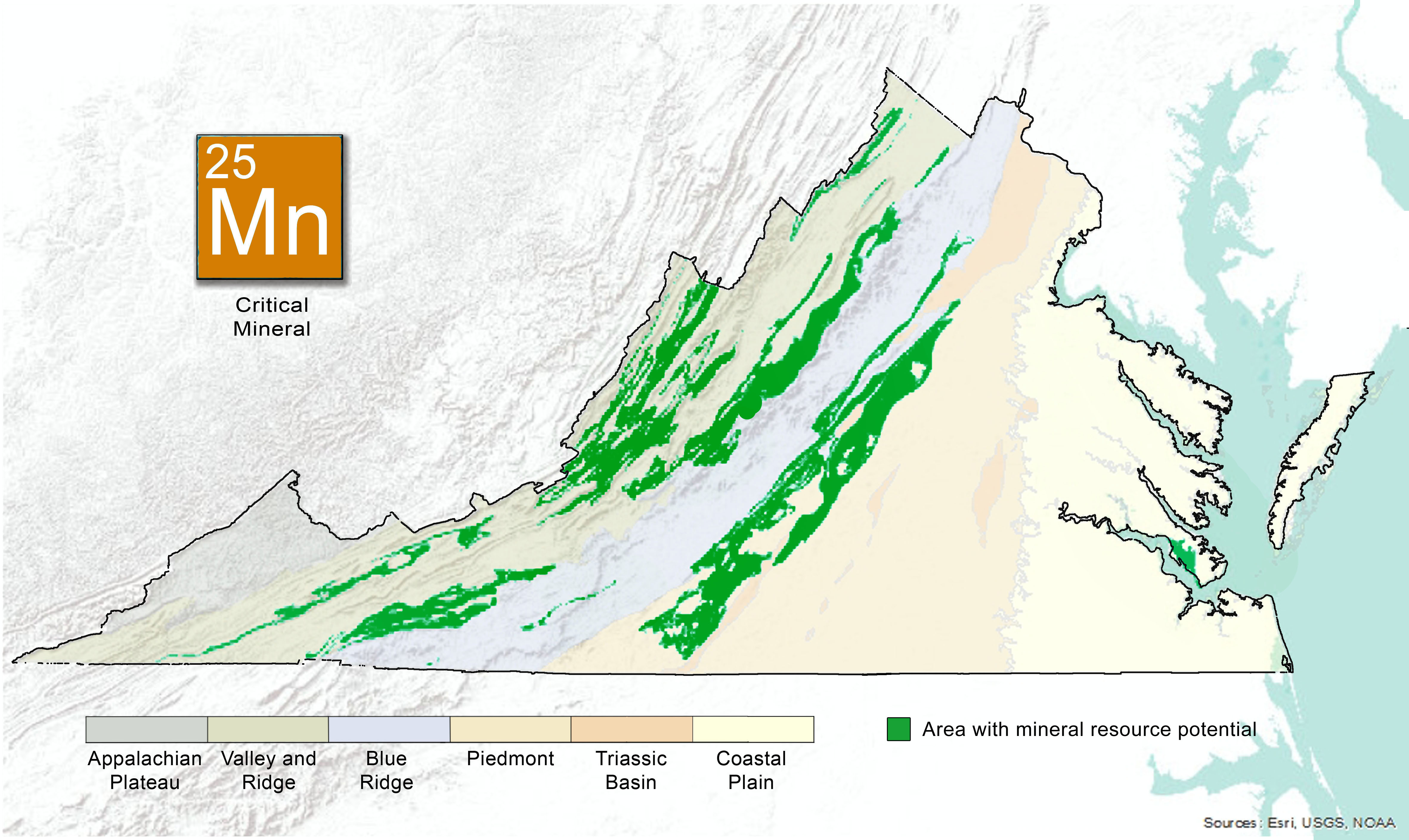

In Virginia, the primary ores of manganese (pyrolusite, cryptomelane, psilomelane, manganite) occur in residual and replacement deposits, and supergene enrichments associated with chemical weathering mineral systems (Table 2). In the Valley and Ridge geologic province, manganese deposits formed in Paleozoic sedimentary and carbonate host rocks in two main mineralized belts described as the 'West Foot of the Blue Ridge Manganese District' (eastern belt), and the 'Western Valley and Ridge District' (western belt) (Pegau, 1958). The eastern belt extends approximately 100 miles from Front Royal in Warren County in the north to just southwest of Waynesboro in Augusta County. Here, residual and replacement manganese deposits consisting of nodules of psilomelane, manganite, pyrolusite, and wad (manganese oxide mixtures) formed in clay-weathered zones at the lower contact of the Cambrian-age Shady Dolomite with the underlying Erwin Formation (Stose and others, 1919). In the western belt, widely dispersed manganese deposits are scattered from Frederick County in the north to Scott County to the southwest. In Shenandoah and Frederick counties, manganese deposits in the Mineral Ridge area occur as strata-bound replacement bodies in lower Devonian-age Oriskany Formation sandstone and Helderberg Formation limestone. In Tazewell, Bland, and Giles counties (Maxwell-Narrows, Flat Top Mountain, and Round Top Mountain), manganese formed as strata-bound replacements within the Cambrian-Ordovician Knox Group dolostones (Stose and Miser, 1922). The ore minerals include psilomelane, wad, pyrolusite, and manganite in residual clays or in manganese-cemented chert nodules.

Manganese residual and replacement deposits also occur in association with Neoproterozoic metasedimentary rocks in the western Piedmont geologic province, known as the 'James River-Roanoke River Manganese District' (Espenshade, 1954). In this case, the source of manganese for the breccia- and vein-hosted deposits in quartzite rocks may have been a formation of marble, where manganese-enriched calcareous sediments were originally deposited as part of a marine chemocline mineral system (Table 2).

Small deposits of manganese oxides in Proterozoic-age rocks in the Blue Ridge geologic province have been described as supergene enrichments associated with structurally-controlled massive spessartine garnet-quartz veins (Jonas, 1942). The northeast trending orientation of these vein deposits and close proximity to the massive sulfide deposits in the Gossan Lead mining district suggest a similar geologic setting, where marine sedimentary exhalative deposits formed in an ancient basin brine mineral system (Table 2) have been intensely modified by structural deformation and metamorphic recrystallization.

Manganese in Industry

Metallurgical grade manganese ores consumed in steelmaking typically contain >44 percent manganese by weight. Although deposits of this grade are known in the U.S., most resources are small in extent and presently not economically viable to mine. The U.S. currently produces small quantities of lower grade manganese ores mainly for non-metallurgical applications, but essentially is 100 percent reliant upon manganese imports. The main sources of imported manganese are from deposits mined in South Africa, Australia, China, and Mexico.

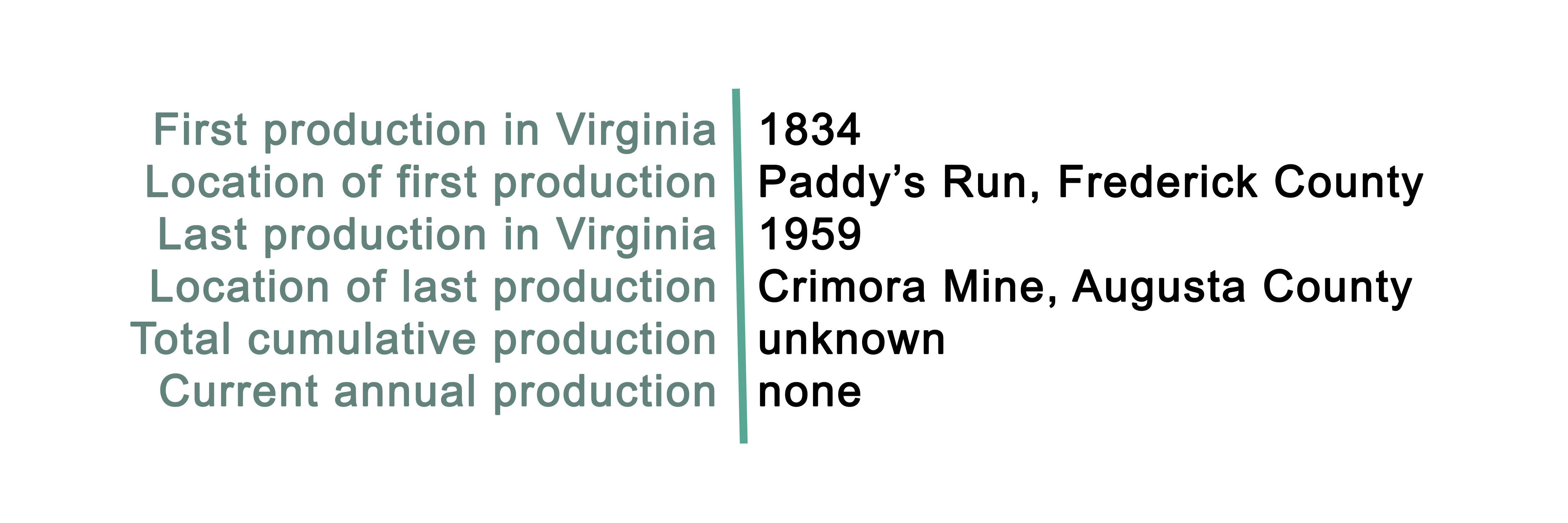

There is an extensive history of manganese mining in Virginia, yet the potential for new discoveries of economic resources of this critical mineral commodity are considered relatively low. Historically, manganese has been mined in numerous locations, with the most economically significant mining occurring in the Valley and Ridge province. Manganese was first extracted in 1834, although commercial production did not begin until about 1867 (Gooch, 1955). Annual production records indicate that between 1867 and 1950 over 378.3 thousand tons of ore grading >35 percent Mn were produced, together with about 163.7 thousand tons of lower quality manganiferous ore grading 10-35 percent Mn.

Although most manganese mining ended by the late 1940s, several historic mines reopened in the 1950s due to the commencement of the Federal Government Stockpiling Program. Annual production reached about 23 thousand tons and was predominantly sourced from the eastern Valley and Ridge district (Gooch, 1955). All mining of manganese in Virginia ceased in 1959, however, with the end of the stockpiling program and its subsidies in 1958.

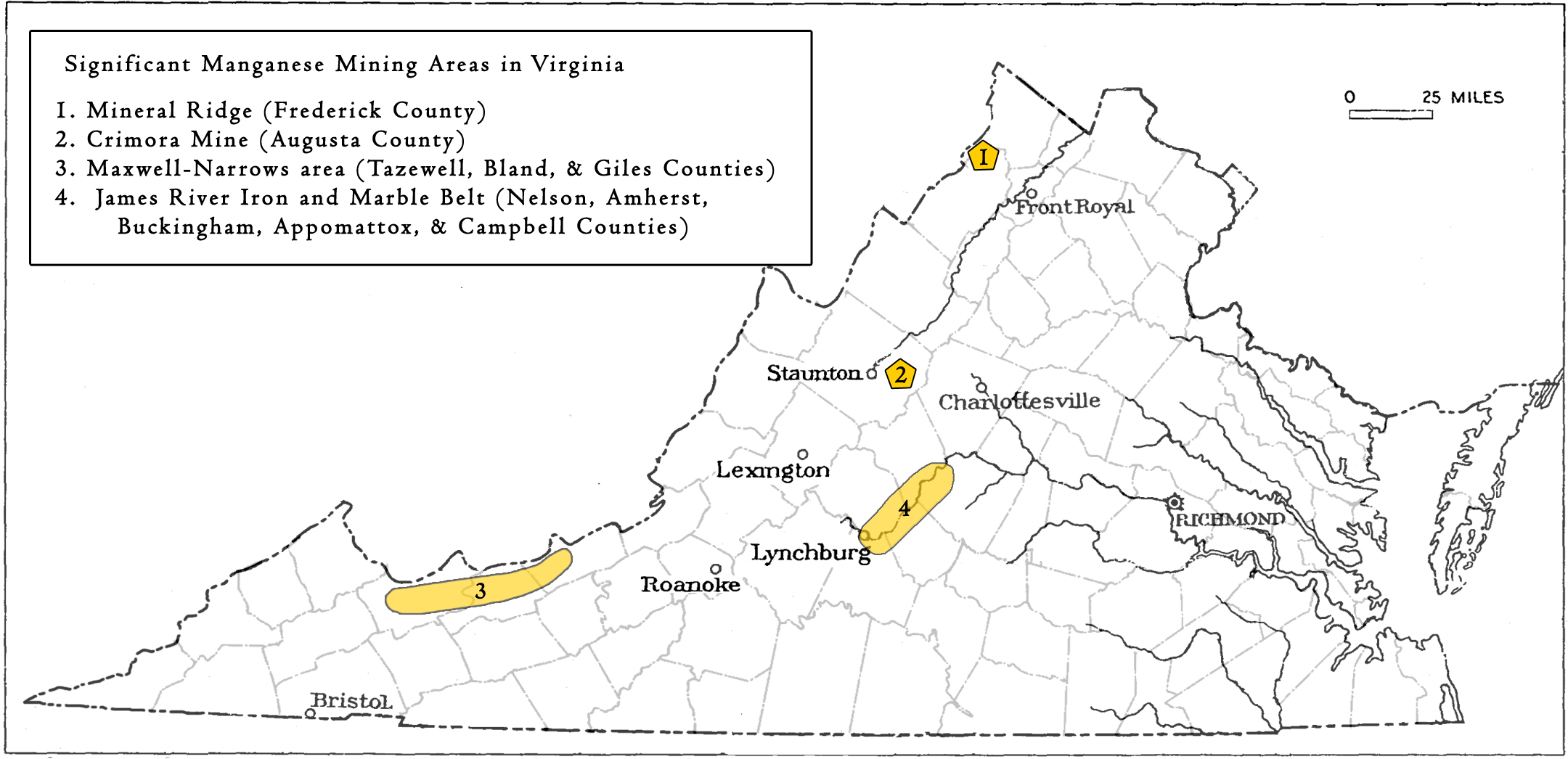

Significant manganese mining areas in the Valley and Ridge and Piedmont provinces

The first area to be mined for manganese in Virginia was the western valley and ridge district, at Mineral Ridge in Frederick County. Operations here began as early as 1834, when manganese ore was identified. In the Mineral Ridge area there were several significant mines and prospects including Paddy's Run, Nelson prospects, and the Moses Orndorff prospect.

Augusta CountyThe largest producing mine in Virginia, and at times the largest producer in the nation, was the Crimora mine, located In Augusta County, which operated nearly continuously from 1867 to 1958. During the seven-year period from 1885 to 1891, this mine yielded over 123 thousand tons of high-grade manganese ore (Pegau, 1958; Watson, 1907; Stose and others, 1919). The ore minerals include rounded nodules of psilomelane (mixed Mn-oxides), manganite (Mn3+O(OH)), pyrolusite (MnO2), wad, and limonite. The mined ore at this deposit contained about 46 percent manganese, 2 percent iron, and 8 percent silica on average (Watson, 1907).

Tazewell, Bland, and Giles CountiesAnother important location for manganese mining in the western Valley and Ridge district is the Maxwell-Narrows area, stretching from Tazewell through Bland and into Giles Counties (Stose and Miser, 1922). The ore minerals throughout this area include psilomelane, wad, pyrolusite, and manganite in residual clays or in manganese-cemented chert nodules. Mines in this district cumulatively produced more than 30 thousand tons of high-grade ore by 1942, with more in reserve (Ladd and Stead, 1944).

Several mines and prospects for manganese operated historically in Bland County. Producing over 30 thousand tons of high-grade manganese from the minerals psilomelane and pyrolusite, mines in these districts operated during World War I until 1942 (Ladd and Stead, 1944). The psilomelane is sourced from fractures, joints, and bedding planes within Devonian sandstone in the Flat Top Mountain District (eastern Bland County), and from residual clay over Silurian limestone in the Round Mountain District (western Bland County) (Ladd and Stead, 1944).

The majority of manganese ore mined in this area originated from the Stange and Arms Mines of the Flat Top Mountain District in Bland County (Ladd and Stead, 1944). These mines were first worked in 1917 from several pits. The ore was processed at nearby washing and jigging plants. According to Ladd and Stead (1944), five cars of ore were shipped in the first year of production, followed by over 16 thousand tons of 35 percent manganese concentrate between 1918 and 1940. Although the site was considered largely mined out by the early 1940s, the U.S. Bureau of Mines assessed the site to determine how much recoverable ore remained in 1941. Exploratory trenches and drill holes (up to 153 feet deep) revealed some potential ore in the sandstone but only trace amounts within the residual clay. Several other successful mines in the Flat Top Mountain District operated during the first half of the 20th century, but recovered moderate amounts or lower quality ore (Ladd and Stead, 1944).

In the Round Mountain District in Bland County, several mines operated during the first half of the 20th century, including Round Mountain Mine, which produced the most manganese in this district. Almost 2,400 tons of ore was recovered from the series of openings at this site with grades up to 47 percent Mn between the years 1941 and 1942. The manganese at the Round Mountain Mine was discovered in rich pockets of residual clay (Ladd and Stead, 1944). Similar to the Flat Top Mountain District, the Round Mountain District was also assessed by the U.S. Bureau of Mines to determine how much recoverable ore remained in 1942. Exploratory pits, shafts, trenches, and drill holes revealed traces of manganese in 60 percent of the drill cores and 50 percent of the pits, with only a few trenches containing promising ore (Ladd and Stead, 1944).

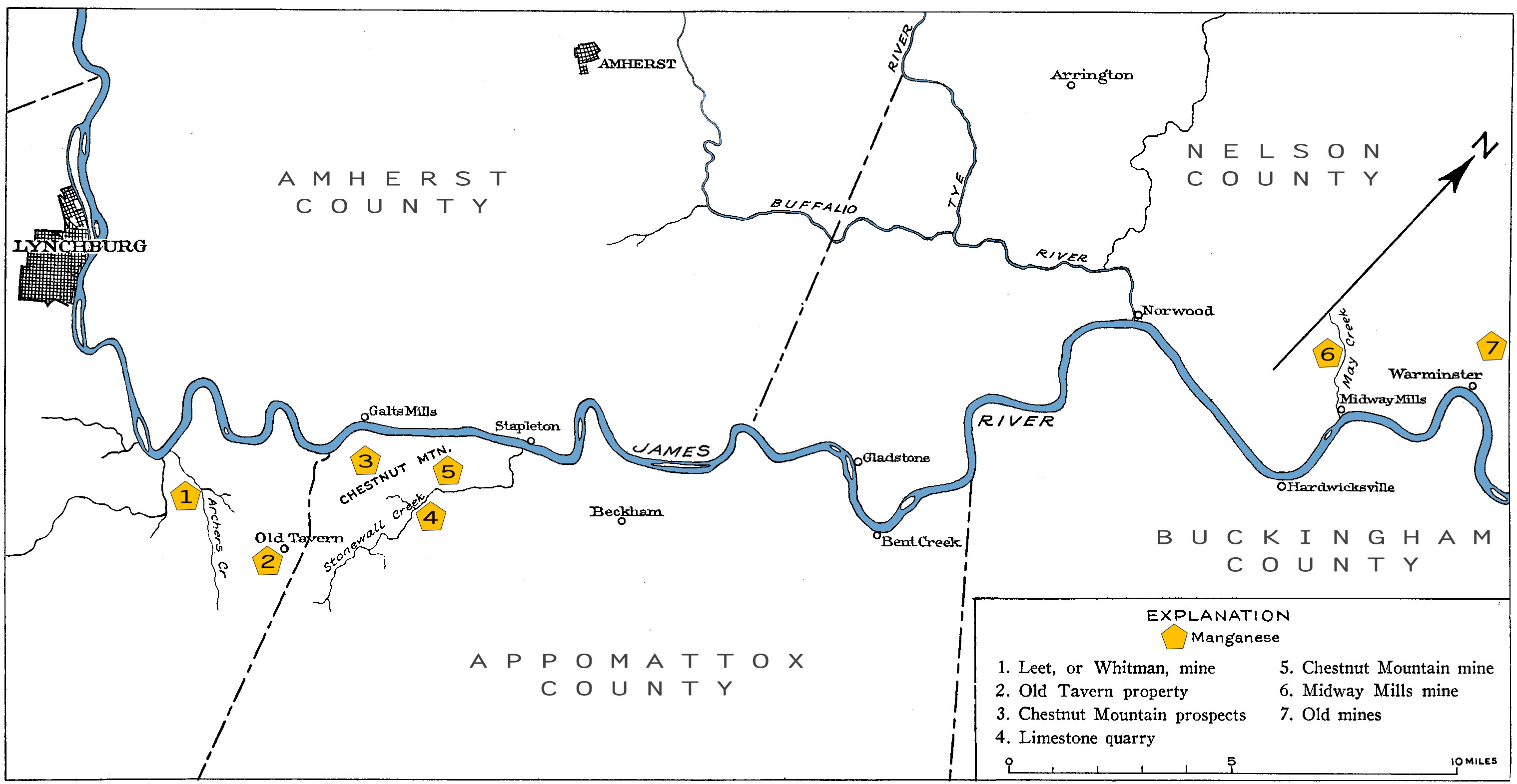

Manganese mines and prospects of the James River Iron and Marble Belt. Modified from Furcron, 1935.

Manganese has also been mined with iron in the Piedmont province. Several counties have workable deposits related to near-surface weathering (residual decay) of limestone and schist (Furcron, 1935). Many mines in the James River Valley successfully produced during a mining boom for iron and manganese in 1880 (Furcron, 1935). The James River Iron and Marble Belt (northeast of Lynchburg) cumulatively produced thousands of tons of manganese ore during the latter half of the 19th century.

Selected References:

Cannon, W.F., and Force, E.R., 1983, Potential for high-grade shallow-marine manganese deposits in North America, in Shanks, W.C., ed., Cameron volume on unconventional mineral deposits: New York, N.Y., American Institute of Mining, Metallurgical, and Petroleum Engineers, p. 175-189.

Espenshade, G.H., 1954, Geology and mineral deposits of the James River-Roanoke River manganese district, Virginia: U.S. Geological Survey Bulletin 1008, 155 p.

Force, E.R., and Cannon, W.F., 1988, Depositional model for shallow-marine manganese deposits around black shale basins: Economic Geology, v. 83, p. 93-117.

Fortier, S.M., Nassar, N.T., Lederer, G.W., Brainard, J., Gambogi, J., and McCullough, E.A., 2018, Draft Critical Mineral List - Summary of Methodology and Background Information - U.S. Geological Survey Technical Input Document in Response to Secretarial Order No. 3359: U.S. Geological Survey Open-File Report 2018-1021, 15 p.

Furcron, A.S., 1935, James River iron and marble belt, Virginia: Virginia Geological Survey Bulletin 39, 124 p.

Gathright, T. M., Henika, W. S., and Sullivan, J. L., 1978, Geology of the Crimora quadrangle, Virginia: Virginia Division of Mineral Resources, Publication 13, with geologic map.

Gooch, E.O., 1955. Current manganese operations in Virginia, Virginia Division of Geology, Virginia Minerals v. 1, n. 5.

Hofstra, A.H., and Kreiner, D.C., 2020, Systems-Deposits-Commodities-Critical Minerals Table for the Earth Mapping Resources Initiative: U.S. Geological Survey Open-File Report 2020-1042.

Jonas, A.I., 1942, Manganese-bearing veins in southwestern Virginia: Virginia Geological Survey Reprint Series No. 5; reprinted from Economic Geology, Vol 37, No. 5, p. 408-423.

Knechtel, M.M., 1943. Manganese deposits of the Lyndhurst-Vesuvius district, Augusta and Rockbridge counties, Virginia: U. S. Geol. Survey Bull. 940-F, p. 163-198.

Ladd, H.S. and Stead, F.W., 1944. Manganese deposits of the Flat Top and Round Mountain districts, Bland and Giles counties, Virginia, U.S. Geological Survey Bulletin 940-H, 245 p.

Miller, R. L., 1944, Geology and manganese deposits of the Glade Mountain district: Virginia Geological Survey Bulletin 61, 150 p.

Pegau, A.A., 1958, Virginia manganese minerals and ores, Virginia Division of Mineral Resources, Mineral Resources Circular No. 7, 24 p.

Stead, F. W., and Stose, G. W., 1943, Manganese and quartzite deposits in the Lick Mountain district, Wythe County, Virginia: Virginia Geological Survey Bulletin 59, 16 p.

Stose, G. W., Miser, H. D., Katz, F.J., and Hewett, D.F., 1919, Manganese Deposits of West Foot of the Blue Ridge, Virginia: Virginia Geological Survey Bulletin 17.

Stose, G. W., and Miser, H. D., 1922, Manganese deposits of western Virginia: Virginia Geological Survey Bulletin 23, 206 p.

Sweet, P. C., 1983, Mineral industries and resources of Virginia: Virginia Division of Mineral Resources, 1:500,000-scale map. U.S. Geological Survey, 2020, Mineral Commodity Summaries 2020: U.S. Geological Survey, 200 p.

Watson, T. L., 1907, Mineral Resources of Virginia: Lynchburg, Virginia, Jamestown Exposition Commission (available as Virginia Division of Mineral Resources, 2003, Digital reprint of T. L. Watson's 1907 Mineral resources of Virginia: Virginia Division of Mineral Resources Publication 175, [CD-ROM; 2003, September 1].

Additional Resources:

U.S. Geological Survey, National Minerals Information Center, Manganese Statistics and Information

U.S. Geological Survey, 2020, Mineral Commodity Summaries 2020: U.S. Geological Survey, 200 p.

U.S. Geological Survey, Critical Mineral Resources of the United States - Economic and Environmental Geology and Prospects for Future Supply, Professional Paper 1802.

.jpg)