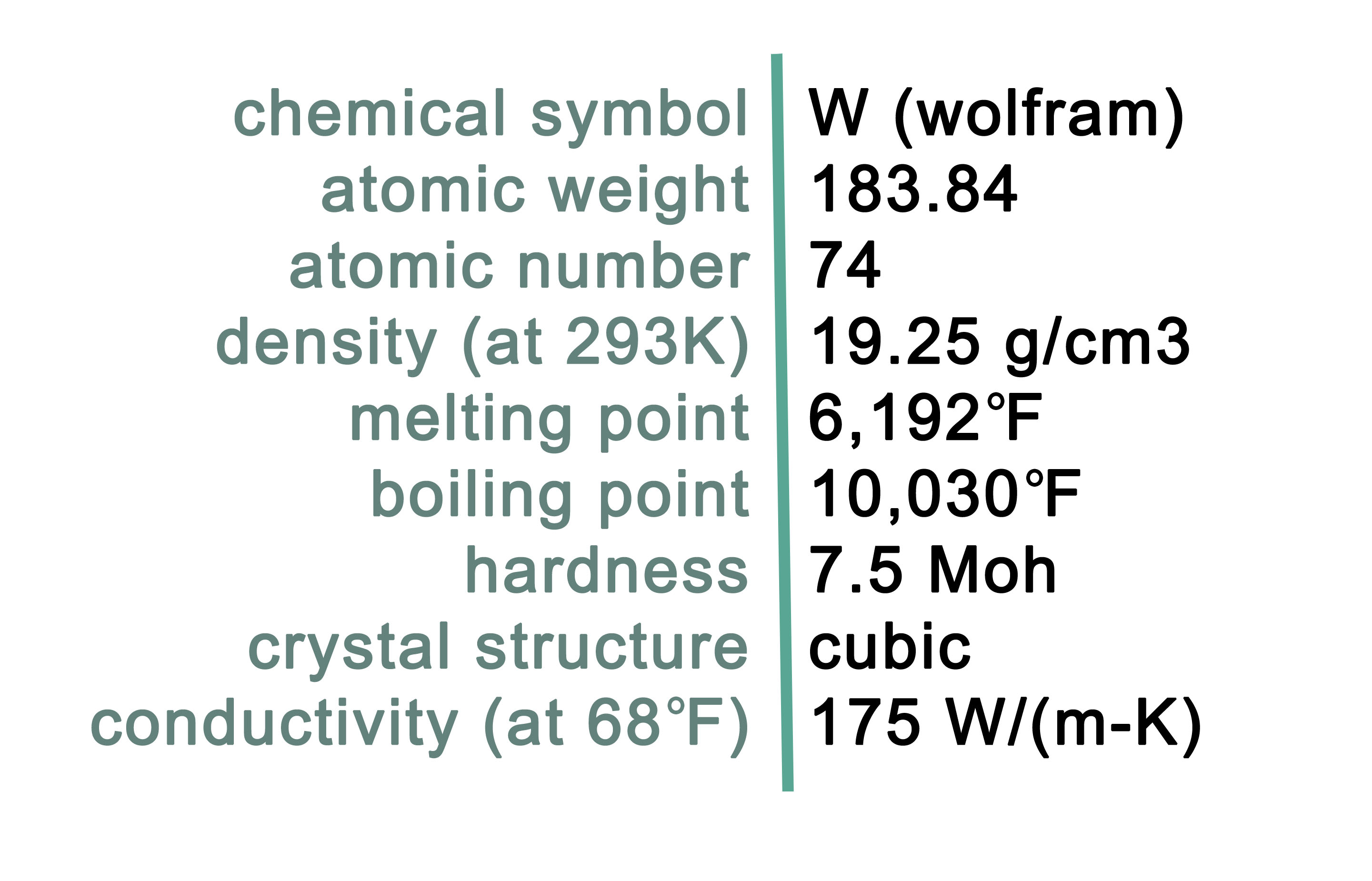

Characteristics of Tungsten

Tungsten is an element that is highly resistant to corrosion and is a good thermal and electrical conductor. Pure tungsten is a steel-gray metal with a high melting point and excellent corrosion resistance. Its chemical symbol is W. Natural tungsten deposits are commonly in the form of the minerals listed in table 1.

| Mineral Name | Chemical Formula | Specific Gravity | WO3 % |

|---|---|---|---|

| Wolframite | (Mn,Fe) WO4 | 7.40 gm/cc | 76.46 |

| Ferberite | Fe2+ (WO4) | 7.58 gm/cc | 73.34 |

| Hübnerite | MnWO4 | 7.15 gm/cc | 76.60 |

| Scheelite | CaWO4 | 5.9 - 6.1 gm/cc | 80.52 |

Table 1: Minerals containing the element tungsten

Uses of Tungsten

Tungsten is considered a "critical mineral" in domestic metallurgical applications that serve aerospace, defense, energy, electronics, and telecommunications technologies (Fortier and others, 2018). Tungsten is used to produce metal alloys for applications requiring high temperatures and high wear resistance. Due to its strength, tungsten is mostly used in carbide parts for cutting (such as drill bits) and wear-resistant applications in construction, metalworking, mining, and the oil and gas drilling industry. Tungsten is also used to make alloys and specialty steels for welding applications and the production of electrodes, filaments, wires, other electrical components. Tungsten is used for electronics, heating, and for the production of incandescent light bulb filaments, cell phones, televisions, and microwave ovens.

Tungsten Geology

Tungsten forms in hydrothermally altered rocks that have undergone medium- to high-grade metamorphism, such was the case during the geologic events that formed the Appalachian Mountains. During this time the entire east coast of ancient North America was compressed - rock that made up the land was faulted, heated, and folded. Heated fluids were forced through cracks and faults and effected the growth of certain minerals, such as scheelite, ferberite, hübnerite, tungstite, and wolframite, which contain tungsten. Veins of the tungsten-mineralized quartz can be found spider-webbed through granitic rocks. These rocks have since been exposed on or near the Earth's surface.

| Mineral System | Deposit Type | Geologic Provinces |

|---|---|---|

| Porphyry or Climax | Post-magmatic sheeted quartz veins in greisen | Piedmont |

Table 2: Prospective tungsten mineral systems, deposit types (Hofstra and Kreiner, 2020), and geologic provinces in Virginia

Tungsten in Industry

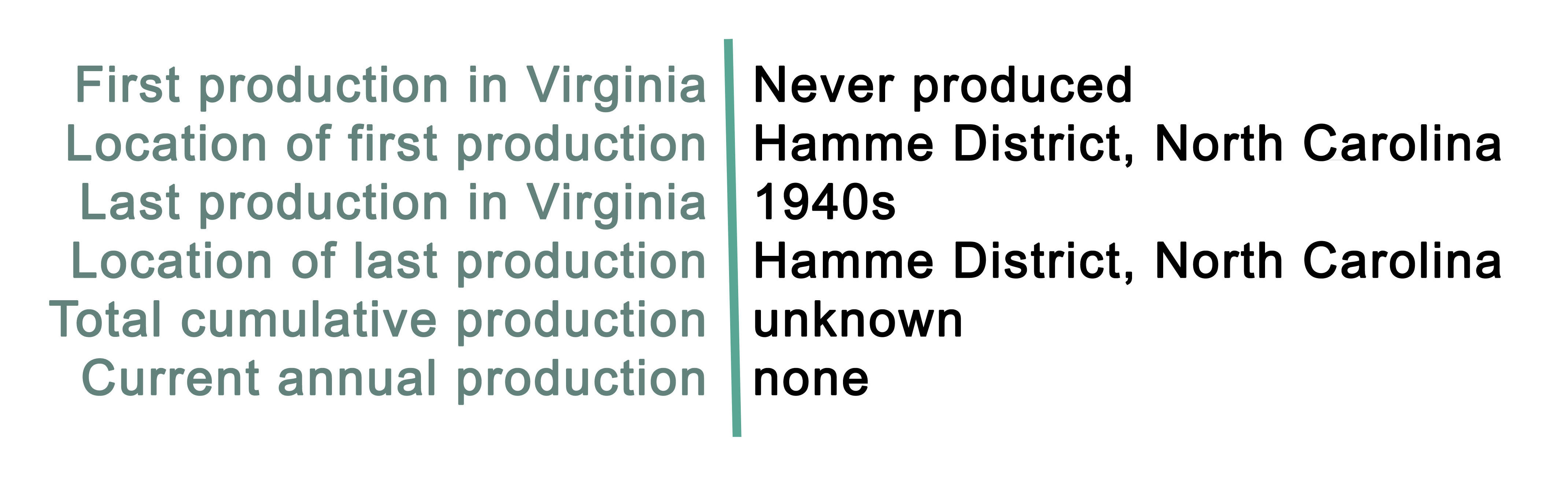

Although the U.S. maintains a supply of tungsten in the National Defense Stockpile, approximately 50 percent of tungsten is imported from China, Bolivia, Germany, and Canada. Occurrences within the United States are primarily in the western United States - Arizona, California, Colorado, Idaho, Montana, Nevada, New Mexico, Texas, Utah, Washington, and Alaska. Smaller deposits are known in other states across the country, including North Carolina and Virginia. Deposits of tungsten have been mined in the United States since the late 1800s but largely ceased in the 1980s.

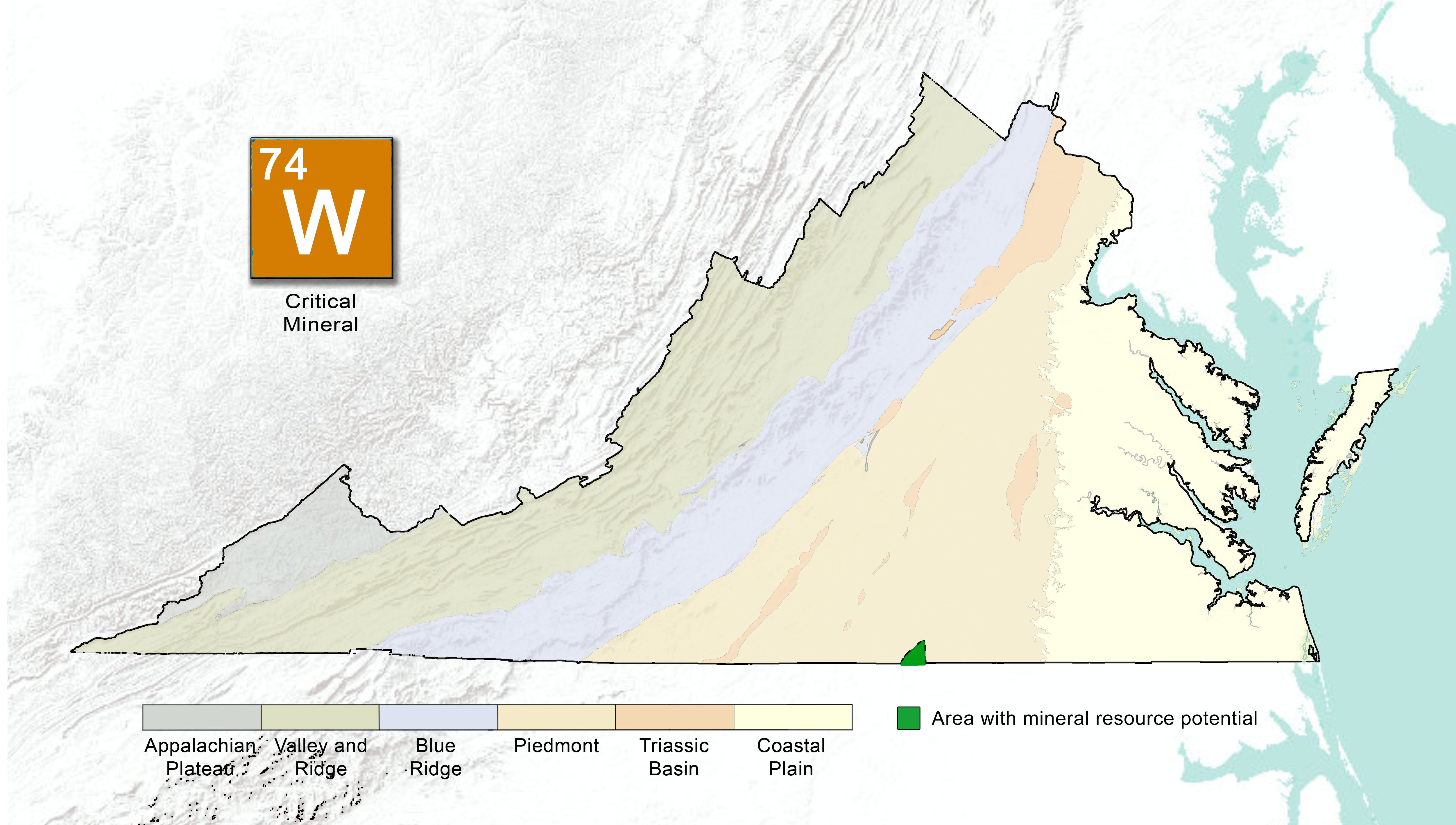

In May of 1942, Richard and Joseph Hamme discovered deposits of tungsten in northern North Carolina and purchased the property from Haile Mines, Inc. By 1945, the Tungsten Mining Corporation had formed. From the time of its discovery through 1963, 1.1 million tons of tungsten trioxide (WO3) from workings in over fifty vein occurrences had been produced (Foose and others, 1980). The area, called the Hamme Mining District, extends for approximately 30 miles and across the Virginia border at its northernmost tip.

Tungsten-mineralized quartz veins located in the Hamme mining District in northern Vance County, North Carolina are known to extend northward into southern Mecklenburg County, Virginia near Boydton. Between 1942 and 1963, the Hamme District produced an estimated 1.1 million tons of tungsten trioxide (WO3) from workings in more than fifty vein occurrences including the major deposit at the Tungsten Queen mine (Foose and others, 1980). Lawrence (1968) noted that in addition to tungsten significant quantities of lead, zinc, gold and silver were also recovered in the District.

The geologic setting of the Hamme District is dominated by a north- northeast trending lens-shaped mass of albite granodiorite emplaced within greenschist-facies metavolcanic rocks of the Carolina slate belt (Espenshade, 1947; Parker, 1963). Steeply dipping hübnerite (MnWO4)-enriched quartz veins, with lesser amounts of scheelite (CaWO4), occur as sheeted veins and discontinuous segments ranging from a fraction of a meter in width up to about 33 feet within highly-deformed fracture and shear zones near the western contact of the granodiorite with metavolcanic strata. Associated minerals include minor amounts of fluorite, pyrite, chalcopyrite, sphalerite, galena, among other sulfides (Argyle, 1946). In the northern pan of the District, the mineralized veins are mainly oriented northwest, while in the central and southern portions of the District the veins trend predominantly northeast and north, respectively (Espenshade, 1947). Based on mineral textural evidence, including the apparent formation of euhedral hübnerite crystals in openspace vein fillings, Foose and others (1980) concluded that the post-magmatic hydrothermal mineralizing events occurred prior to at least two periods of later regional deformation.

In Virginia, several hübnerite-quartz vein occurrences considered possible extensions of the Hamme District were investigated by the U.S. Bureau of Mines in 1944-45. Drilling and trenching in the Taylor prospect area in Mecklenburg County revealed mineralized veins with diverse orientations, but generally striking north and dipping 45 degrees to the east (Argyle, 1946). The main mineralized vein extended about 560 feet along strike and measured 12- 20 inches in width. Samples from the vein indicated the average grade to be about 2.2 percent WO3, together with trace amounts of lead, copper, and silver. One sample contained 10.21 percent WO3. Although the high-grade tenor of the ore was considered prospective, the investigation concluded that the quantity of known ore was insufficient for a commercial operation. Unfortunately, exploration in the area today is constrained by the presence of Kerr Reservoir, which covers most of the prospective region.

Selected References:

Argyle, B.E., 1946, Exploration of the Mecklenburg County, Virginia tungsten area: U.S. Bureau of Mines Report of Investigations R.I. 3857, 6 p.

Espenshade, G.H., 1947, Tungsten deposits of Vance County, North Carolina and Mecklenburg County, Virginia: U.S. Geological Survey Bulletin 948-A, 17 p.

Foose, M.P., Slack, J.E, and Casadevall, T., 1980, Textural and structural evidence for a predeformation hydrothermal origin of the Tungsten Queen deposit, Hamme District, North Carolina: Economic Geology v. 75, n. 4, p, 515-522.

Fortier, S.M., Nassar, N.T., Lederer, G.W., Brainard, J., Gambogi, J., and McCullough, E.A., 2018, Draft Critical Mineral List - Summary of Methodology and Background Information - U.S. Geological Survey Technical Input Document in Response to Secretarial Order No. 3359: U.S. Geological Survey Open-File Report 2018-1021, 15 p.

Hofstra, A.H., and Kreiner, D.C., 2020, Systems-Deposits-Commodities-Critical Minerals Table for the Earth Mapping Resources Initiative: U.S. Geological Survey Open-File Report 2020-1042.

McIntosh, Frank K., 1948, Investigation of the Hamme Tungsten District, Vance County, North Carolina, and Mecklenburg County, Virginia: U.S. Bureau of Mines Reports of Investigations RI-4380, 6 p., 33 figs.

Mitchell, Philip, 2010, Tungsten in Life and Medicine, International Tungsten Industry Association, December 2010 newsletter https://www.itia.info/assets/files/ITIA_Newsletter_12_2010.pdf

Parker, John M., 1963, Geologic Setting of the Hamme Tungsten District North Carolina and Virginia: Contributions to Economic Geology, Geological Survey Bulletin 1122-G

Sweet, P. C., 1983, Mineral industries and resources of Virginia: Virginia Division of Mineral Resources, 1:500,000-scale map.

Sweet, P. C., Good, R. S., Lovett, J. A., Campbell, E. V. M., Wilkes, G. P., and Meyers, L. L., 1989, Copper, lead, and zinc resources in Virginia: Virginia Division of Mineral Resources Publication 93, 185 p.

Watson, T. L., 1907, Mineral Resources of Virginia: Lynchburg, Virginia, Jamestown Exposition Commission, 618 p.

(available as Virginia Division of Mineral Resources, 2003, Digital reprint of T. L. Watson's 1907 Mineral resources of Virginia: Virginia Division of Mineral Resources Publication 175, [CD-ROM; 2003, September 1].

.jpg)