Characteristics of Tantalum

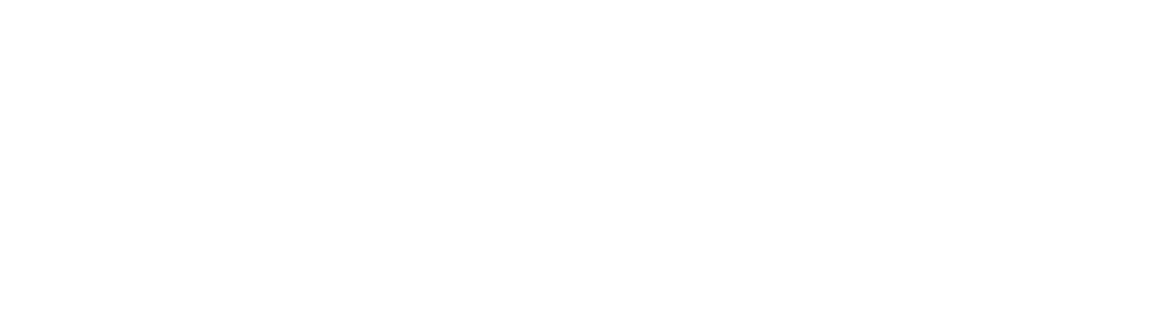

The element tantalum is a hard, dense, silvery metal with the chemical symbol Ta. Tantalum is a lustrous metal. When tantalum is exposed to air, it forms a durable oxide film which is highly resistant to corrosion. Tantalum is also highly resistant to heat and generally non-reactive. Tantalum is a strong and conductive metal that is almost always found together with the element Niobium (Nb). Tantalum does not occur naturally as a pure metal, but is rather bound with oxygen and other elements in minerals such as tantalite (Table 1).

| Mineral Name | Chemical Formula | Specific Gravity | Ta % |

|---|---|---|---|

| Tantalite | (Fe,Mn)Ta2O6 | 6.78 - 8.23 gm/cc | 70.44 - 86.02 |

| Microlite | (Na,Ca)2Ta2O6

| 6.23 gm/cc |

73.7 - 86.0 |

|

| Tapiolite | (Fe,Mn)(Ta,Nb)2O6 | 7.90 gm/cc | ≤ 86 |

| Ixiolite | (Ta,Fe,Sn,Nb,Mn)4O8 | 7.57 gm/cc | 68.96 |

| Wodginite | Mn(Sn,Ta)(Ta,Nb)2O8 | 7.58 gm/cc | 67.5 - 70.1 |

| Columbite | (Fe,Mn)(Nb,Ta)2O6 | 4.6-4.7 gm/cc | 10.95 - 27.50 |

| Strüverite | (Ti,Ta,Fe)O2 | 6.02 gm/cc | 33.1 - 35.5 |

| Pyrochlore | (Na,Ca,Ce)2(Nb,Ti,Ta)2(O,OH,F)7 | 5.27 gm/cc | ≤ 4.3 |

Table 1: Minerals containing the element Tantalum

Tantalum capacitors used for military,

medical, and aerospace technology

Uses of Tantalum

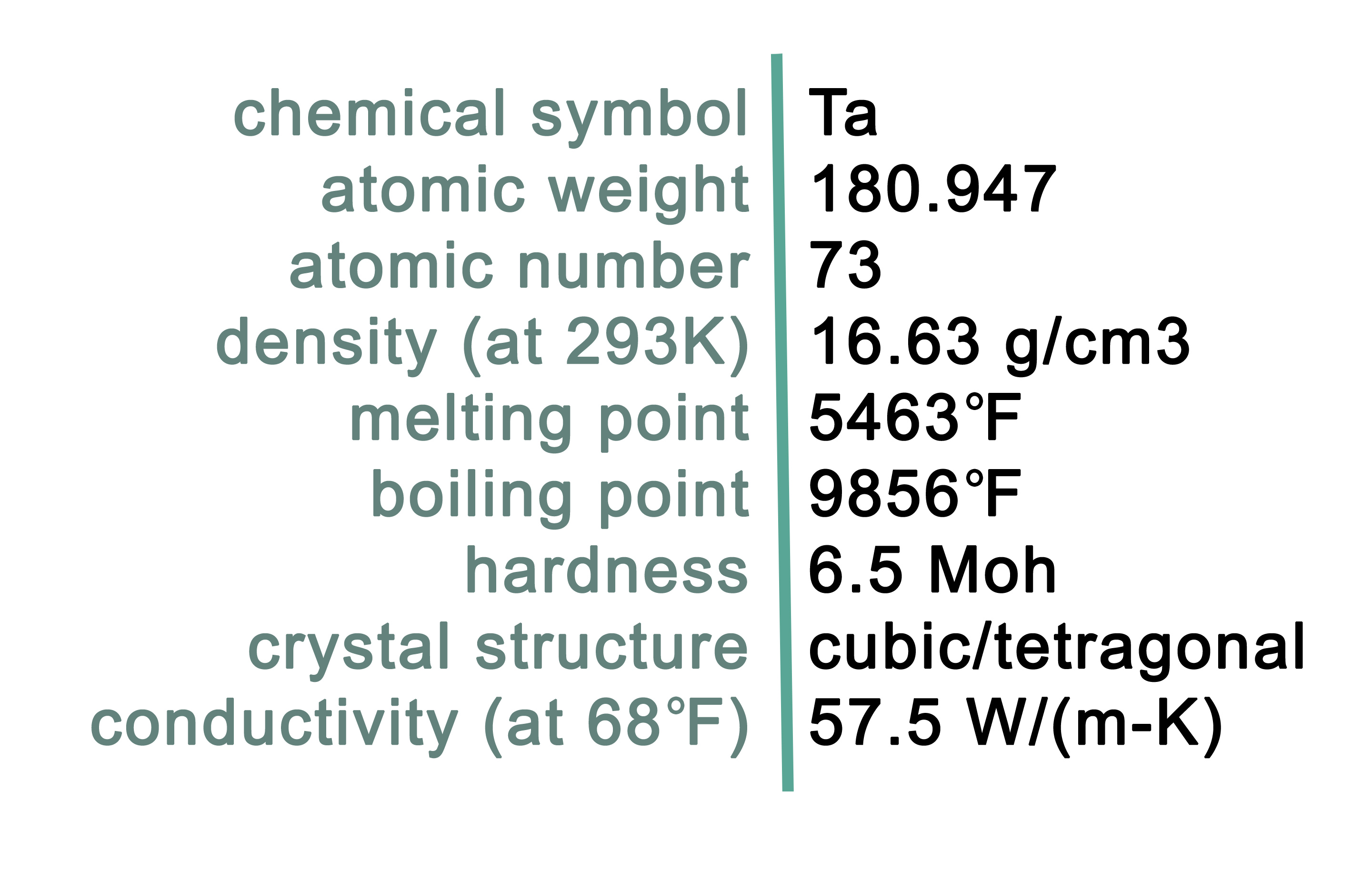

The element tantalum was discovered in 1802, although often confused with niobium. Tantalum is considered a "critical mineral" in domestic metallurgical applications that serve aerospace, defense, energy, electronics, and telecommunications technologies (Fortier and others, 2018). Tantalum is an element that is crucial for technology. Its primary use is as a capacitor or resistor in a variety of electronic equipment, such as computers, cell phones, and medical devices. Tantalum is also used as a metal alloy to improve strength, ductility, and to increase corrosion and heat resistance. Such alloys are used in jet engines, nuclear reactors, and aerospace technology. Its non-reactive nature also makes tantalum ideal for medical implants.

A tapiolite crystal.

Photo credit: Robert Lavinsky

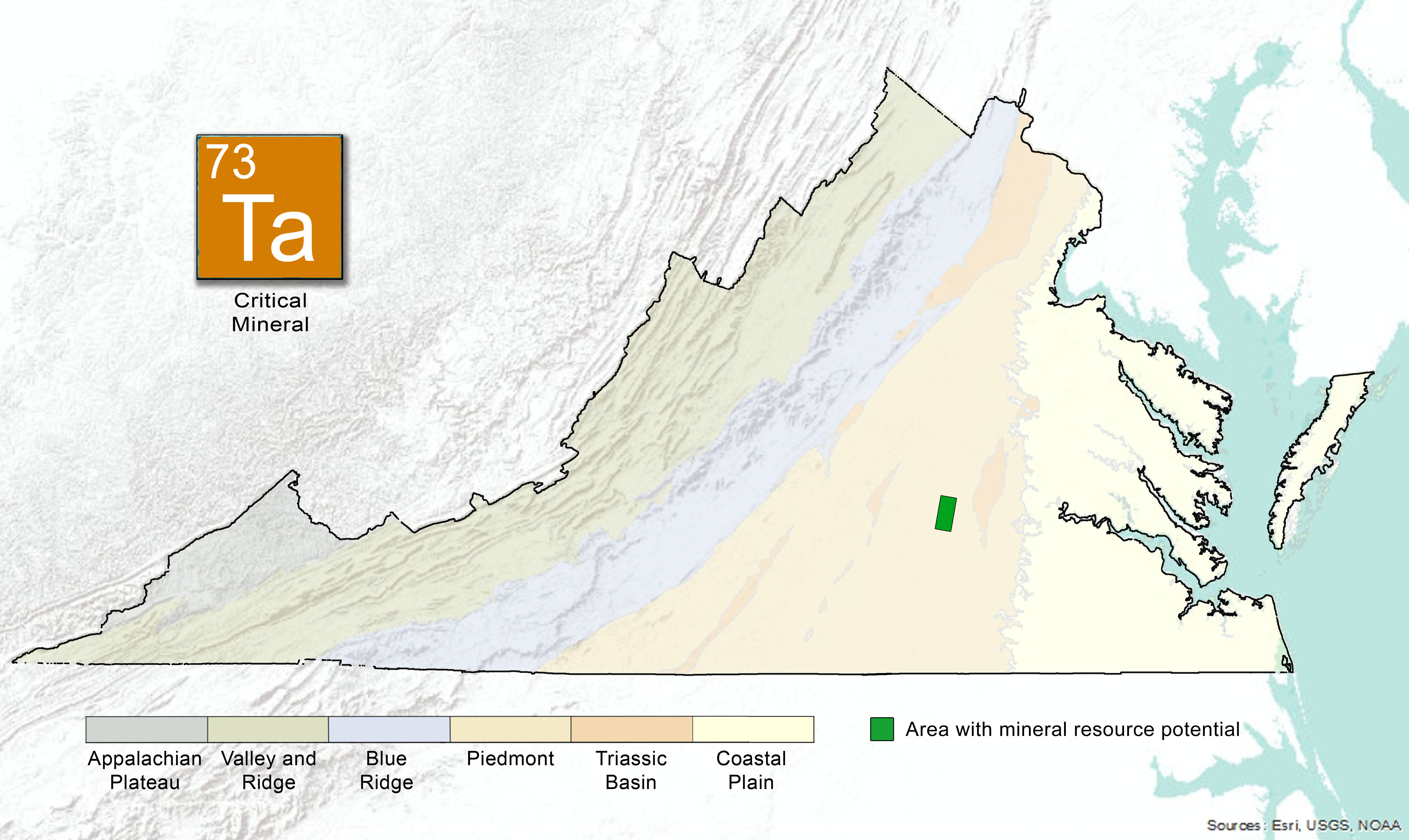

Tantalum Geology

Tantalum forms together with the element niobium in a variety of igneous rocks. Tantalum originates from tectonic plate convergence (during the formation of mountains), or plate divergence (during the formation of ocean basins). During these geologic events, plutons, dikes, and sills of magma intrude into the surrounding rock and cool to form granites and pegmatites. The chemistry of the magma and surrounding rock largely determine which minerals form. Tantalum- and niobium- rich minerals may form in carbonatites (igneous rocks ≥50 percent calcite or dolomite), alkaline granites and syenites (rich in sodium and potassium sourced from the deep mantle), or within hydrothermally altered rare-metal granites. Once such rocks have been exposed to weathering, secondary deposits rich in tantalum and niobium may form as laterites or sedimentary placers.

| Mineral System | Deposit Type | Geologic Provinces |

|---|---|---|

| Climax-type | Pegmatite (NYF) | Piedmont |

| Placer | Columbite, tantalite | Coastal Plain |

Table 2: Prospective tantalum mineral systems, deposit types (Hofstra and Kreiner, 2020), and geologic provinces in Virginia

Tantalum in Industry

The element tantalum is globally distributed, but generally in low concentrations. The U.S. maintains a supply of tantalum in the National Defense Stockpile, but is 100 percent import reliant from Rwanda, Brazil, Canada, and Australia. Mining for tantalum in the United States has not occurred since 1959. Concerns related to mining for tantalum include disruption of the surrounding ecosystem, and potential radioactivity of the tailings which may contain thorium and uranium.

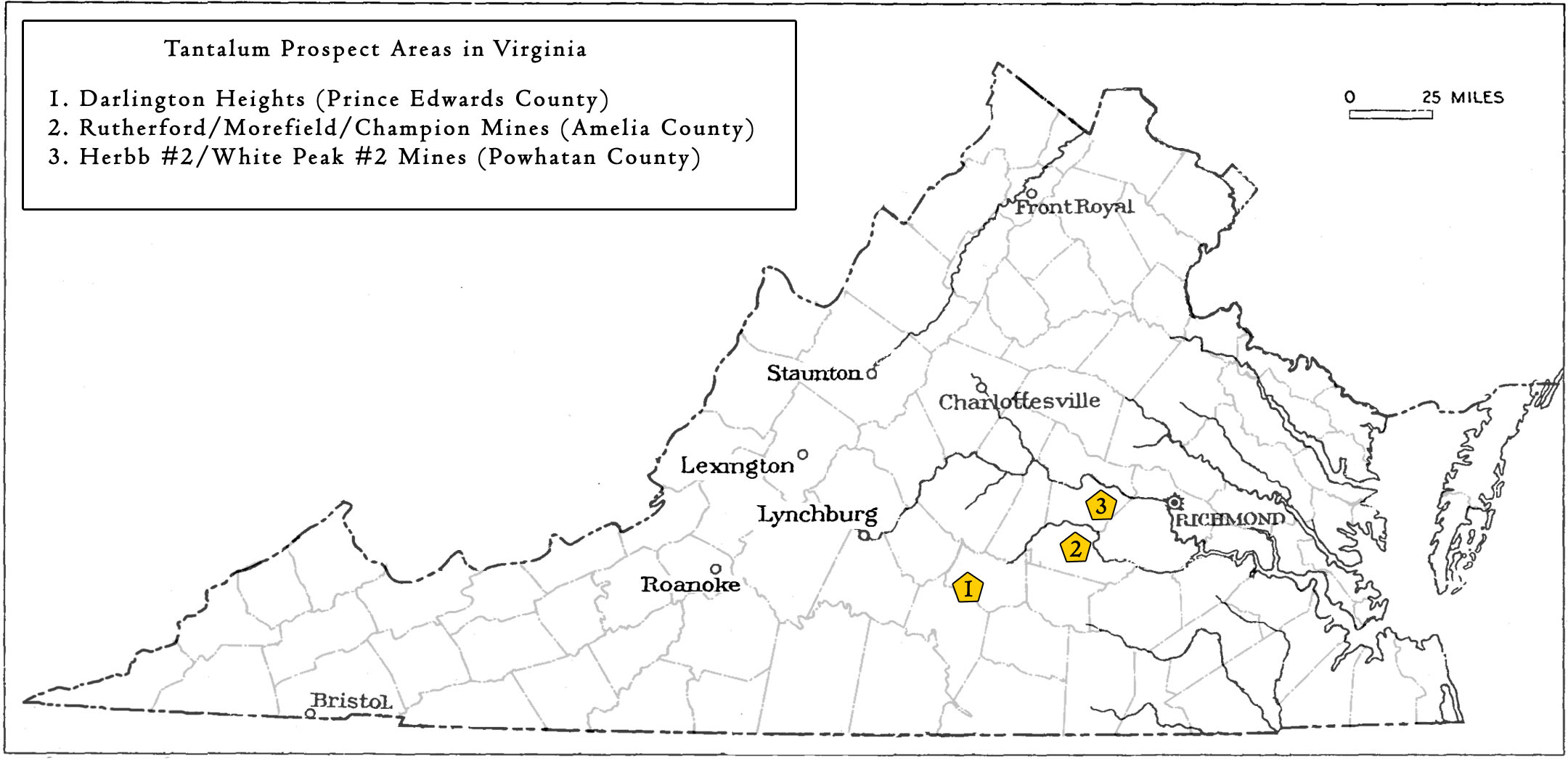

In Virginia, tantalum is primarily found within the minerals tantalite, columbite, wodginite, and pyrochlore or microlite. Such minerals are common in pegmatites that have often been mined for other resources. Although tantalum has not been directly mined in Virginia, several prospects have been identified within the past century.

Locations in Virginia sampled or prospected for tantalum

A small occurrence of pegmatite just east of the town of Darlington Heights in Prince Edward County has yielded several prospecting samples of the mineral columbite containing up to 28.1 percent tantalum (Giannini and Sweet, 1991). This site has not been mined.

Amelia County

One of the Morefield mine shafts.

From Giannini and Sweet, 1991.

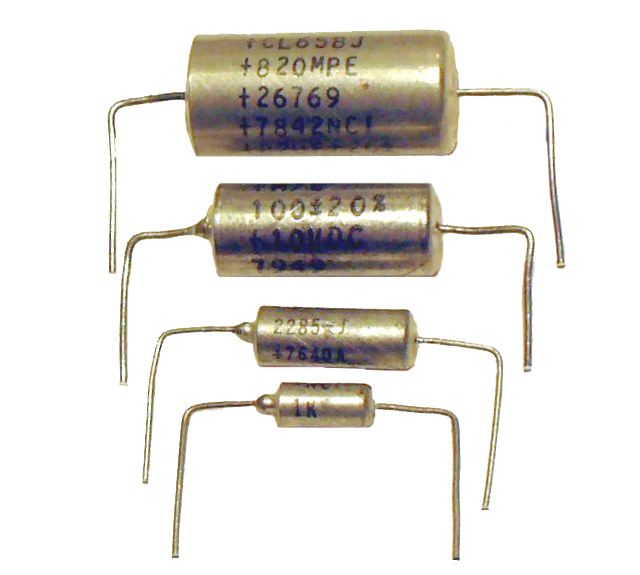

Near the Amelia Court House, the well-known Morefield Mine has provided hundreds of tons of feldspar, mica, beryl, and tantalite-columbite since 1929. Open cuts, pits, trenches, shafts, and drill holes expose and explore the underlying pegmatite, which is a dike at least 1,100 feet in length by 30 feet thick. Tantalum occurs within the minerals columbite and tantalite in a zone of perthite rock. Columbite mineral samples from the Morefield mine have been collected and analyzed several times in the 1980s, and contain approximately 25 percent tantalum. Some of the tantalite crystals are reported to be well formed and weigh as much as half a pound (Lemke and others, 1952). Approximately 1,423 pounds of tantalum-containing minerals were extracted from this site between 1929 and 1944 (Lemke and others, 1952).

A couple miles to the east, the Rutherford pegmatite Mines are also of interest. Here, the underlying Amelia pegmatite has been mined sporadically since at least 1873 for mica and amazonite (Giannini and Sweet, 1991; Lemke and others, 1952). Several open pits and shafts were constructed and mostly mica was removed until the sites were abandoned in 1943. Although the underground workings are flooded, the Rutherford Mines were more recently open to the public for mineral collecting until the 1980s. This location was never mined for tantalum, however chemical analyses of columbite mineral samples from the pegmatite suggest a composition of up to 27.05 percent tantalum.

Also in Amelia County, the Champion mine was heavily worked for mica beginning in 1873. Several open cuts and shafts were dug to access a pegmatite body surrounded by schist and gneiss. Between 1913 and 1914, 200 thousand pounds of mica was extracted, some of which was cut into twelve-inch sheets. Although the site was buried in 1984 and most of the mica has been mined out, samples from the local Amelia pegmatite suggest a relatively high tantalum composition of up to 46.8 percent.

Powhatan CountyIn Powhatan County, two mines produced mica from the underlying Amelia pegmatite. The Herbb Number 2 mine near Flat Rock was open for a short period beginning in 1944. Samples of tantalite and cassiterite obtained in 1991 were reported to contain 33 percent tantalum. Columbite mineral samples from the White Peak Number 2 Prospect (approximately 2 miles southwest of the Herbb No. 2 mine) contain 16.29 percent tantalum. Several pits and trenches were dug here in 1944. Although a small amount of mica was mined, no other commodities were extracted.

Selected References:

Brown, W.R., 1962, Mica and Feldspar Deposits of Virginia: Virginia Division of Mineral Resources, Mineral Resources Report 3, 195 P.

Dietrich, R.V., 1970, Minerals of Virginia: Virginia Polytechnic Institute, Research Division Bulletin.

Fortier, S.M., Nassar, N.T., Lederer, G.W., Brainard, J., Gambogi, J., and McCullough, E.A., 2018, Draft Critical Mineral List - Summary of Methodology and Background Information - U.S. Geological Survey Technical Input Document in Response to Secretarial Order No. 3359: U.S. Geological Survey Open-File Report 2018-1021, 15 p.

Giannini, W.F., and Sweet, P.C., 1991, Tantalian and Niobian Resources in Virginia, Virginia Division of Mineral Resources, Publication 115.

Hofstra, A.H., and Kreiner, D.C., 2020, Systems-Deposits-Commodities-Critical Minerals Table for the Earth Mapping Resources Initiative: U.S. Geological Survey Open-File Report 2020-1042.

Lemke, R.W., Jahns, R.H., and Griffitts, W. R., 1952, Mica deposits of the southeastern Piedmont, pt. 2. Amelia District, Virginia: United States Geological Survey Professional Paper 248-B, p. 103-139.

Mallet, J. W., 1877, On sipylite, a new niobate from Amherst County, Virginia: American Journal of Science (3d), v. 14, p. 397-400.

Mitchell, R.S., 1977, Some noteworthy minerals from Virginia: Rocks and Minerals, v. 52, no. 5, p. 221-229.

Niobium and Tantalum, Chapter M in Critical Mineral Resources of the United States - Economic and Environmental Geology and Prospects for Future Supply. U.S. Geological Survey Professional Paper 1802-D

Pegau, A.A., 1932, Pegmatite Deposits of Virginia, Virginia Geological Survey Bulletin 33. Rocks & Minerals: 60:165.

.jpg)