Feldspar is one of the most abundant minerals in the earth's crust. The feldspars include a range of compositions with the general chemical formula xAl(Al,Si)3O8 where x can be sodium (Na) and/or calcium (Ca) and/or potassium (K). The sodium and potassium-enriched compositions are known as alkali feldspars, which are primarily used in glass manufacture and ceramics. In glass, alkali feldspar improves hardness and durability. In ceramics, the feldspar is used as a flux to lower melting temperatures during the firing process. The calcium-enriched compositions are known as plagioclase feldspars and these provide a source of alumina to promote chemical and physical strength in fiberglass and other glass-making applications. Economic deposits of feldspar occur in a variety of rock types including anorthosite, aplite, nepheline syenite, and in pegmatites.

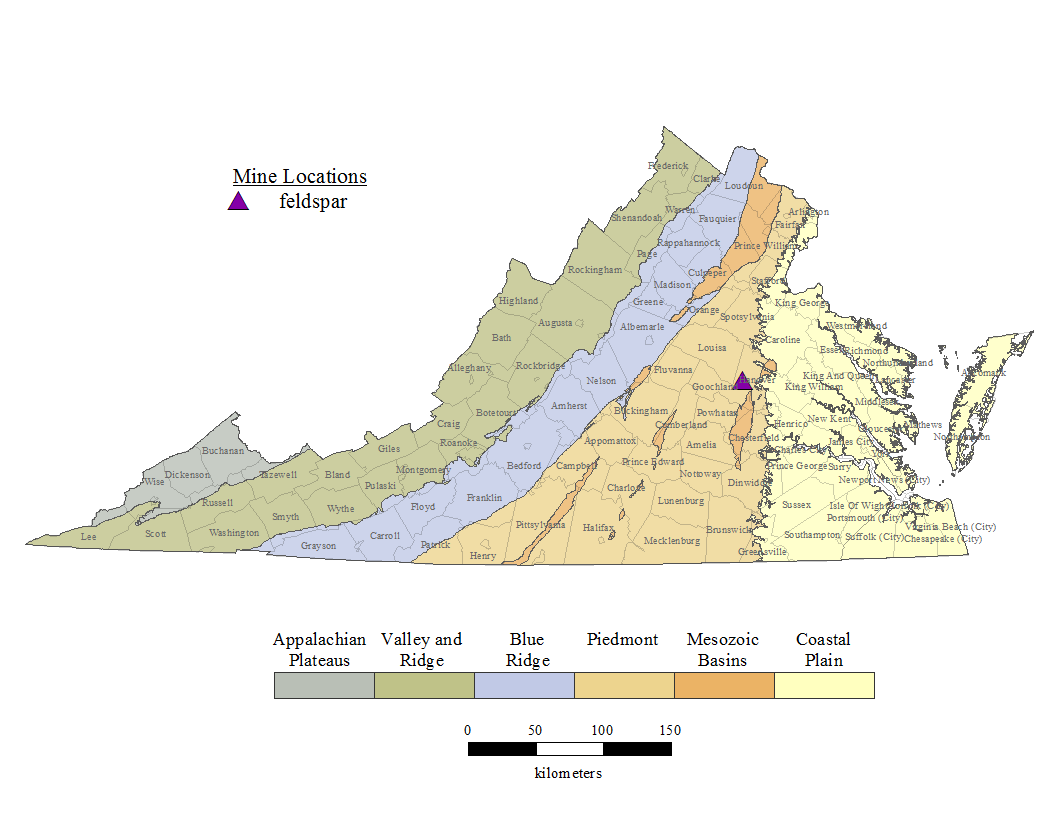

Historically, feldspar in Virginia was mined for use in the ceramics industry, for abrasives, and for gemstones (amazonite) (Pegau, 1932). Prior to about 1907, feldspar was mined primarily as a by-product of mica mining. The deposits occur in pegmatite rocks in Bedford, Prince Edward, and Amelia Counties.

Currently industrial grade feldspar is produced at one mine in Virginia from granitic aplite, a fine-grained igneous rock consisting mainly of quartz and feldspar. The rock occurs as part of the Montpelier metanorthosite igneous complex located in Hanover County. Early mining interest in the area was focussed mainly on co-occurrences of titanium-bearing rutile, but starting in about 1957 the mining company began recovering feldspar for use in the glassmaking industry. Today, U. S. Silica Corporation continues to produce feldspar used in the container glass, insulation fiberglass and recreational sand industries. The mined ore is extracted using open pit methods, crushed, classified, and dried on site. Heavy minerals including rutile and ilmenite are removed from the material by electrostatic and magnetic processes. The processed material is then transported by truck and rail to markets.

Year of first production in Virginia: 1880s

County locations with commercial mining (past and present): Amelia, Amherst, Bedford, Hanover, Prince Edward

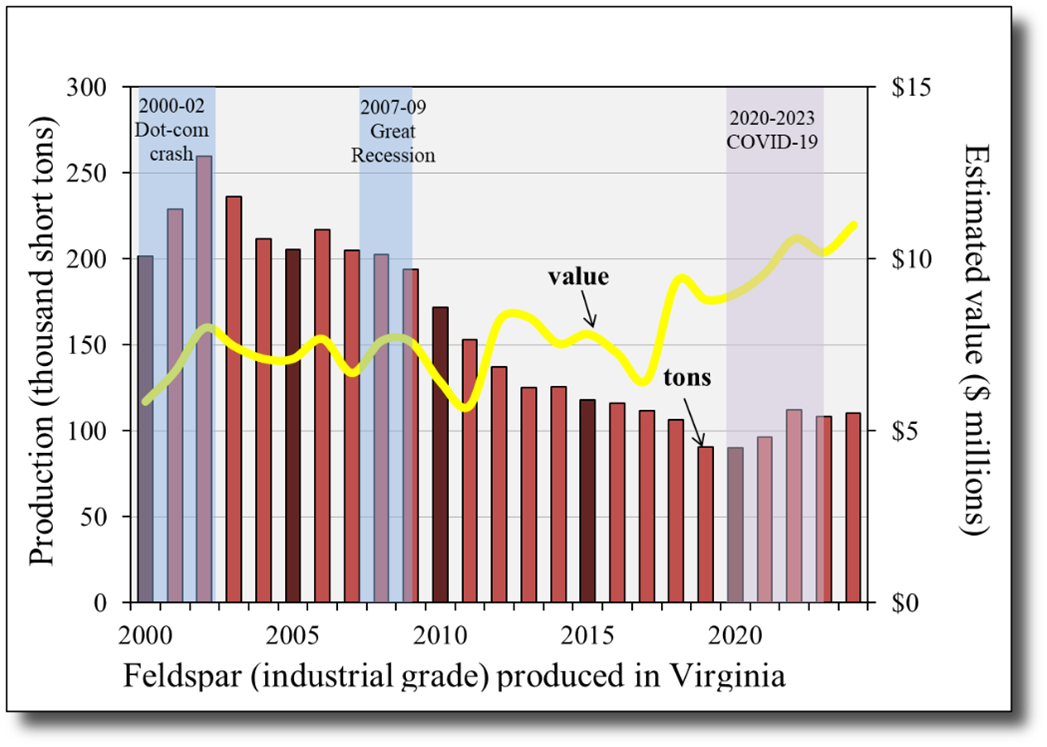

Quantity produced in 2024: 110.2 thousand short tons

Estimated value of produced minerals in 2024: $11.0 million

Annual production and estimated value1

1 Estimates of annual mineral value are calculated using tonnages reported to Virginia Energy and commodity sales prices reported in numerous published and unpublished sources. The prices may include national or global industry averages. The calculated annual values do not necessarily reflect the actual sales prices received by mine operators in Virginia.

Selected References:

Bice, K. L., and Clement, S. C., 1982, A study of the feldspars of the Montpelier andesine anorthosite, Hanover County, Virginia: Geological Society of America Abstracts with Programs,v. 14, p. 5.

Brown, W. R., 1962, Mica and feldspar deposits of Virginia: Virginia Division of Mineral Resources Mineral Resource Report 3, 195 p.

Clement, S. C., and Bice, K. L., 1982, Andesine anorthosite in the Eastern Piedmont of Virginia: Geological Society of America Abstracts with Programs, v. 14, p. 10.

Gilmer, A. K., Enomoto, C. B., Lovett, J. A., and Spears, D. B., 2005, Mineral and fossil fuel production in Virginia (1999-2003): Virginia Division of Mineral Resources Open-File Report 05-04, 77 p.

Owens, B. E. and Dymek, R. F., 1999, A geochemical reconnaissance of the Roseland anorthosite complex, Virginia, and comparisons with andesine anorthosites from the Grenville Province, Quebec: in: A. K. Sinha (editor), Basement Tectonics, v. 13, p. 217-232.

Pegau, A. A., 1932, Pegmatite deposits of Virginia: Virginia Division of Mineral Resources Bulletin 33, p. 3-122.

U.S. Geological Survey, 2020, Feldspar Statistics and Information

Virginia Division of Mineral Resources, 1993, Geologic Map of Virginia: Virginia Division of Mineral Resources, scale 1:500,000.

Watson, T. L., 1907, Mineral Resources of Virginia: Lynchburg, Virginia, Jamestown Exposition Commission, 618 p.

(available as Virginia Division of Mineral Resources, 2003, Digital reprint of T. L. Watson’s 1907 Mineral resources of Virginia: Virginia Division of Mineral Resources Publication 175, [CD-ROM; 2003, September 1].