Characteristics of Aluminum

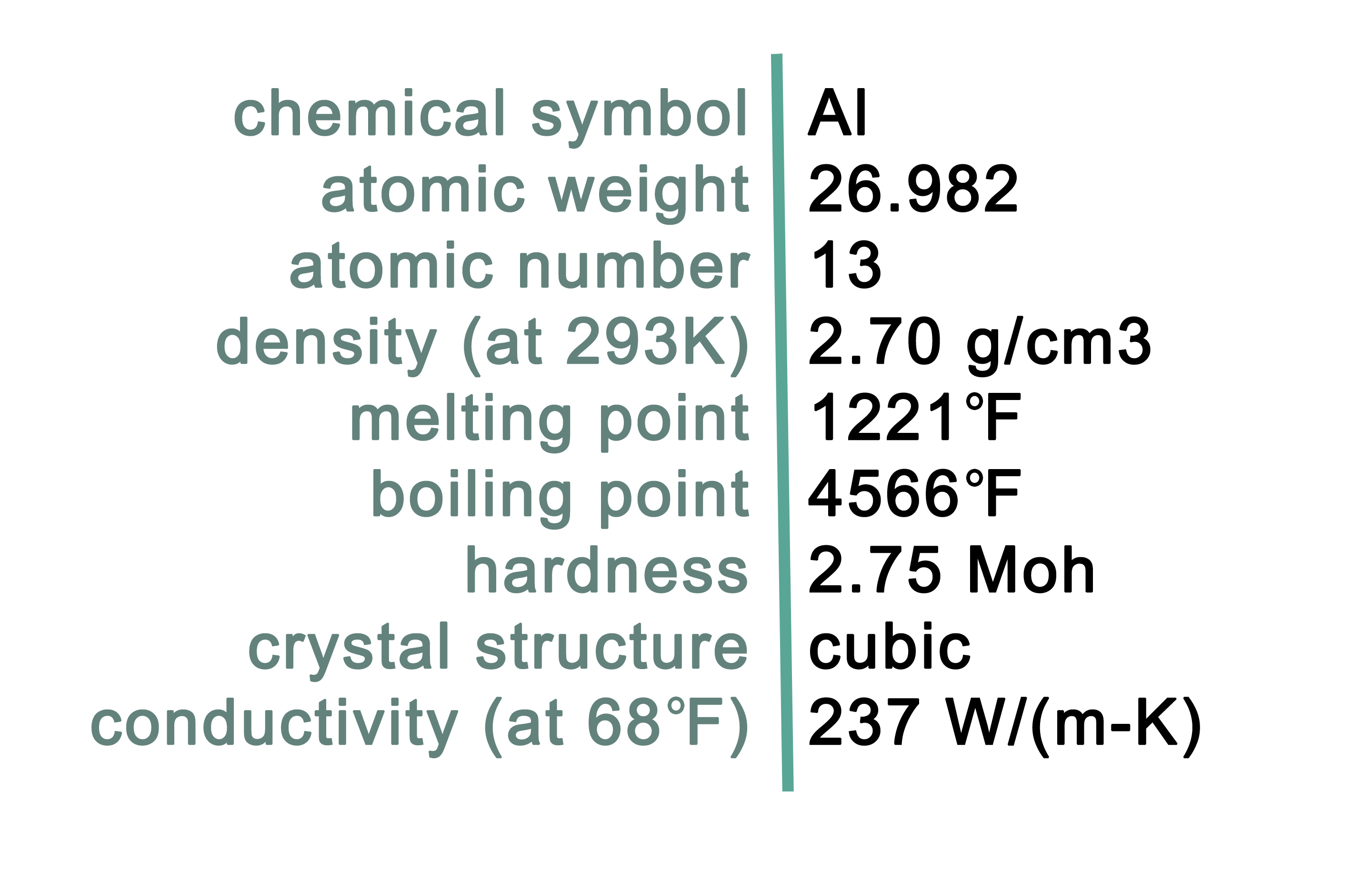

Aluminum a soft silvery metal with the chemical symbol Al. Aluminum is a light-weight, malleable, and ductile metal. It is non-magnetic, has a low density, and is highly conductive. Aluminum is also very durable and highly resistant to corrosion. Because pure aluminum is relatively reactive, it does not occur naturally as a pure metal, but is rather bound with oxygen and other elements in minerals and rocks such as bauxite, which is its primary ore (Table 1).

| Mineral Name | Chemical Formula | Specific Gravity | Al % |

|---|---|---|---|

| Boehmite | BAlO(OH) | 3.04 gm/cc | 44.98 |

| Diaspore | AlO(OH) | 3.38 gm/cc | 44.98 |

| Gibbsite | Al(OH)3 | 2.35 gm/cc | 34.59 |

| Cupalite | (Cu,Zn)Al | 5.19 gm/cc | 29.74 |

| Steinhardtite | Al0.38Ni0.32Fe0.3 | 5.52 gm/cc | 30.00 |

Table 1: Minerals containing the element Aluminum

Aluminum is used to produce aircraft such as this Boeing-747.

Photograph courtesy of Sergey Kustov.

Uses of Aluminum

Aluminum is considered a "critical mineral" in domestic metallurgical applications that serve aerospace, defense, energy, and transportation technologies (Fortier and others, 2018). Aluminum, as alum, has been used by humans since at least the ancient Greek civilization. Scientists were not able to isolate it as an element until 1824. Aluminum is an extremely useful material. It has applications in all sectors of the economy. Many household items are produced with aluminum, including aluminum foil, food and drink packaging cans, and cooking utensils. Aluminum is also used to construct window frames, doors, and for roofing and siding. Aluminum's low density make it desirable in the transportation industry for bicycles, cars, and aircraft. It is critical to the aerospace industry. Aluminum is also used for electronics and technology.

The rock bauxite, with spherical pisolites, is the primary ore of aluminum.

Aluminum Geology

Aluminum is primarily sourced from the rock bauxite. Bauxite is composed of aluminum hydroxide minerals such as gibbsite, boehmite, and diaspore. Bauxite forms in areas of intense weathering of aluminum-containing rocks, such as igneous or metamorphic rocks that are rich in feldspar. Carbonate rocks are also common sources of aluminum. As these rocks weather, they form a residual clay in which original minerals break down, erode away, or are chemically altered. As a highly insoluble element, aluminum can remain to form aluminum-containing minerals. As such minerals develop, they may form concretionary pisolites within the bauxite rock.

| Mineral System | Deposit Type | Geologic Provinces |

|---|---|---|

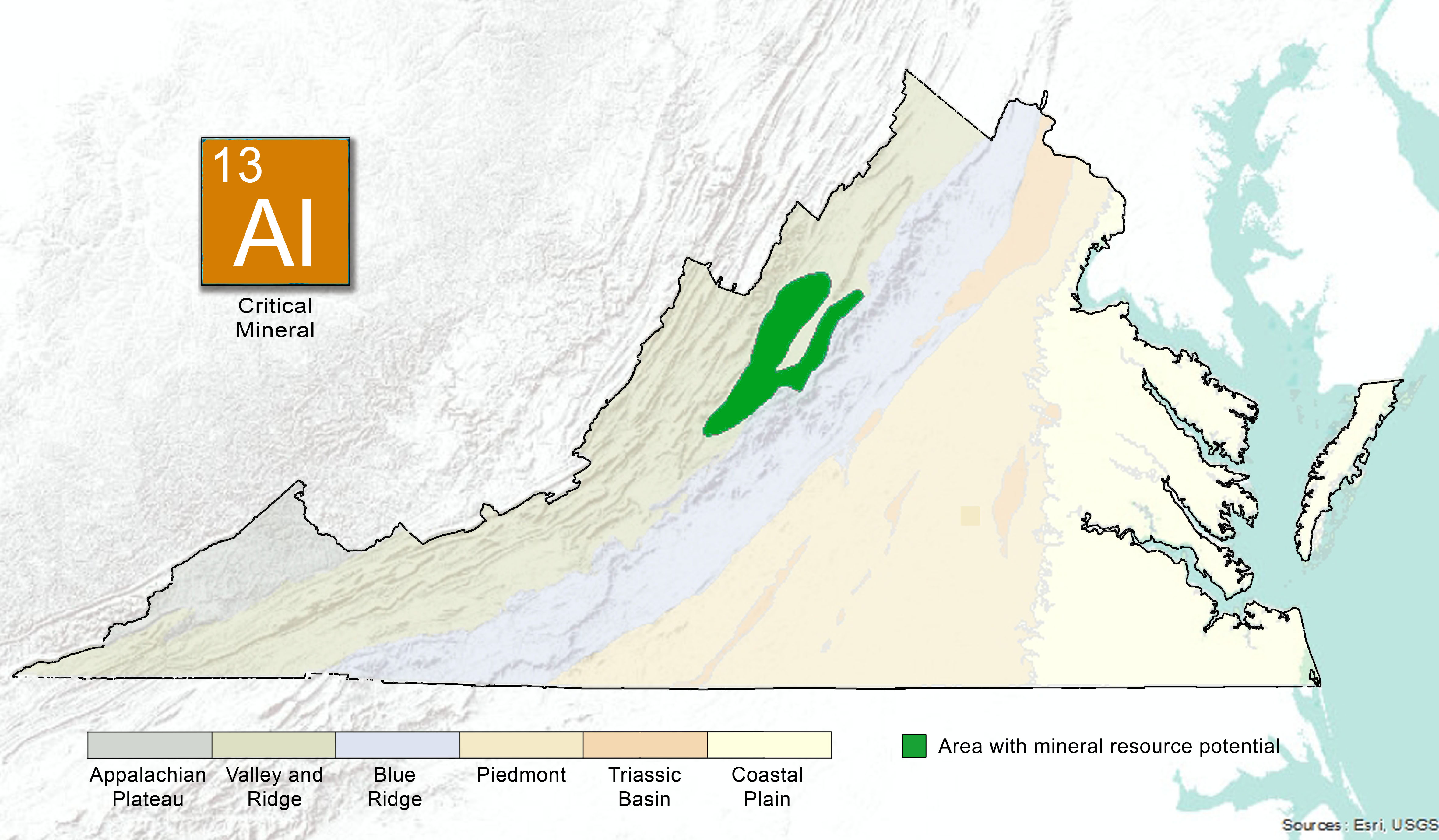

| Chemical weathering | Bauxite / kaolinite | Valley and Ridge (Augusta County) |

Table 2: Prospective aluminum mineral systems, deposit types (Hofstra and Kreiner, 2020), and geologic provinces in Virginia

Aluminum in Industry

The element aluminum is quite common in the Earth's crust and is globally distributed. Although it is common, aluminum is considered a critical commodity because of its extreme usefulness and irreplaceability. The U.S. does not maintain a supply of aluminum in the National Defense Stockpile and is 61 percent import reliant. The United States imports bauxite from Canada, Russia, and numerous other countries. Aluminum is produced from the imported bauxite at several aluminum smelters in the United States (including in South Carolina, New York, Kentucky, Arkansas, and Indiana). A substantial amount of aluminum is also recycled at such smelters. Concerns related to aluminum mining include the release of aluminum into the air, which settles into water systems making it toxic to water-dwelling organisms. Aluminum may also disrupt plant growth in acidic soils. The aluminum smelting process releases harmful greenhouse gases.

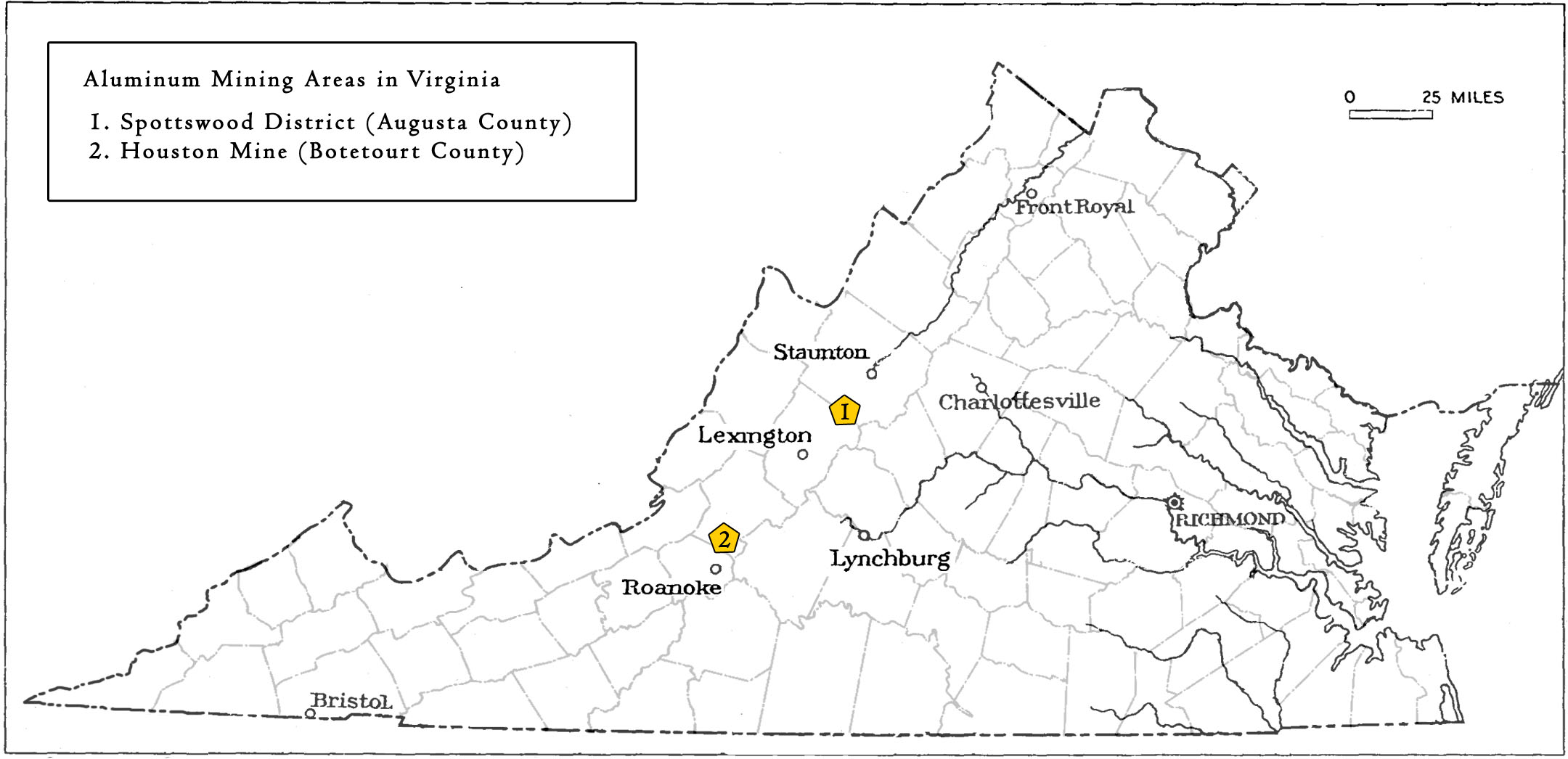

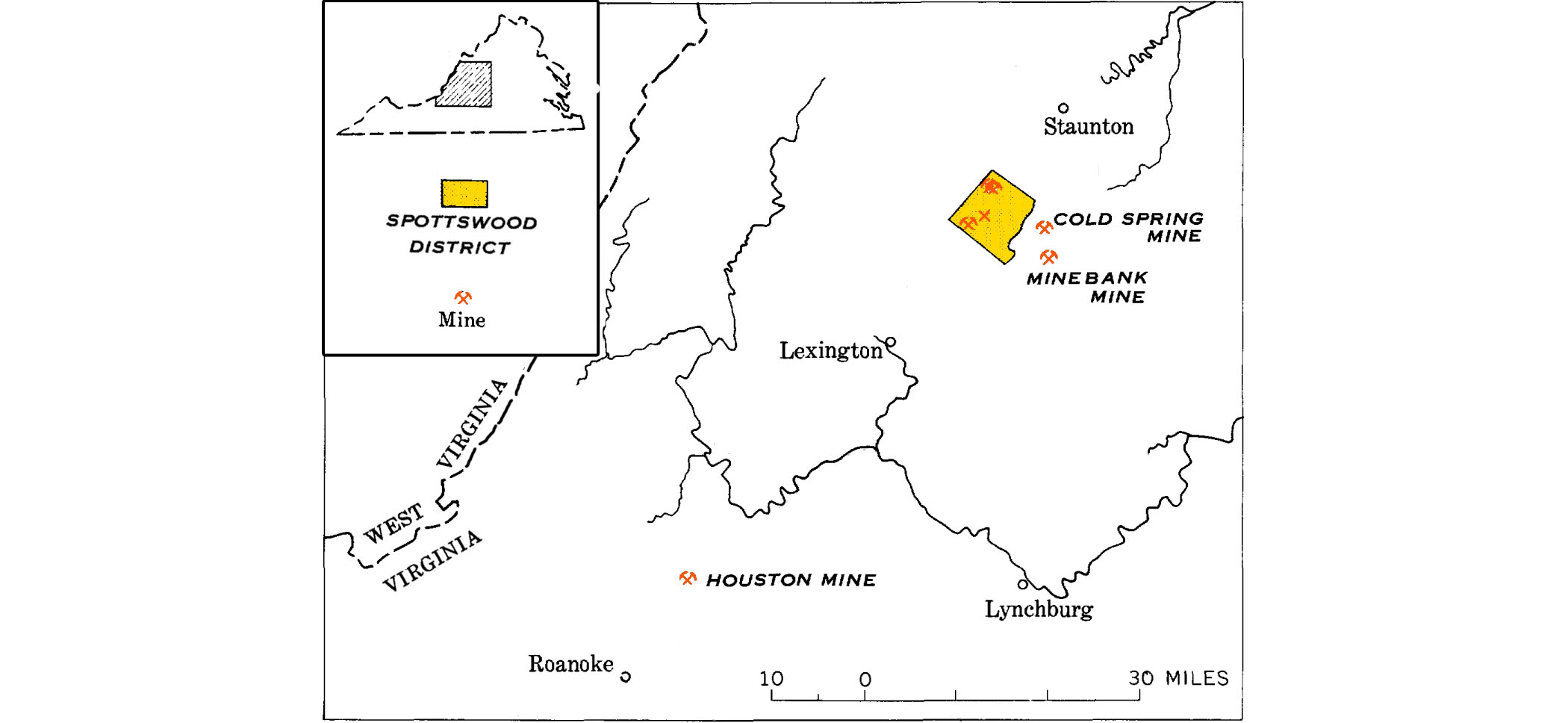

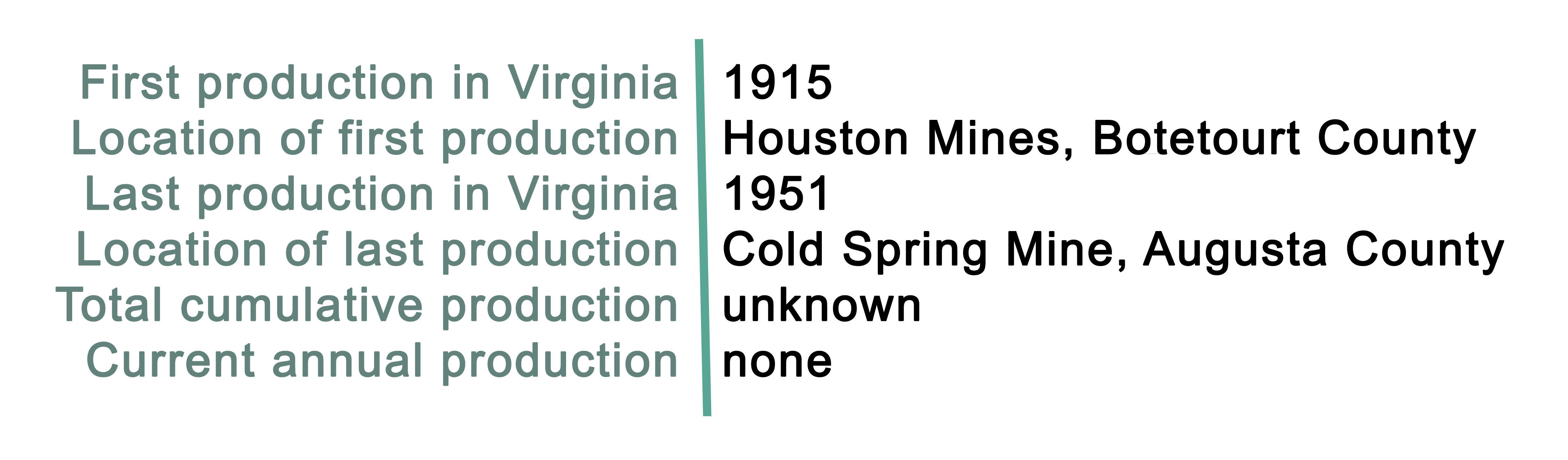

Small deposits of bauxite exist in Virginia. Although most of Virginia's deposits are too small for economic development, several mines were historically in production in the Valley and Ridge. Aluminum from these areas primarily is sourced from the mineral gibbsite and is associated with kaolinite. The bauxite is found with kaolin in pockets surrounded by a residual clay (Warren and others, 1965). Bauxite mining began in 1915 and continued intermittently until 1946 when import of bauxite increased and demand decreased (Warren and others, 1965).

Locations in Virginia mined for aluminum

The Allen Mine pit, north of Spottswood, opened in 1941.

Photograph modified from Warren

and others, 1965.

Several sites of aluminum mining exist in Augusta County. The three most important mines, the Lightner property mine, the Allen Mine, and the Harris Mine, were built within the Spottswood District. This 10-mile stretch of area south of Staunton, has produced the largest quantity of aluminum in Virginia. Bauxite was discovered in this area in 1930. Mined intermittently form 1940-1946, approximately 30 thousand long tons of 49-59 percent grade aluminum oxide (Al2O3) came from these mines during their operation, mostly during 1942-1943 (Warren and others, 1965).

The Lightner Mine near the town of Spottswood opened in 1940. Underlain by limestone of the Conococheague and Stonehenge Formations, bauxite and kaolin have formed within residuum. A pit 10-40 feet deep and 200 feet long was dug into the kaolin and bauxite-rich ore body to expose ore of up to 57.5 percent aluminum oxide (Al2O3).

Approximately 4 miles to the northeast, the Allen Mine opened in 1941. A pit at least 50 feet deep and 120 feet long was excavated to access the ore body within residuum above Beekmantown dolomite. Ore obtained from this location contained 59.2 percent aluminum oxide. Allen Mine operated intermittently until 1946 (Warren and others, 1965).

The Harris Mine, just to the southeast of the Allen Mine, opened in 1942. A 50-foot diameter, 15 foot deep circular pit was excavated and later extended as mining continued through 1942-1943 and again from 1945-1946. The average grade ore from the Harris Mine was measured at 58.0 percent aluminum oxide (Warren and others, 1965).

Detail map of aluminum mines and prospective deposits in Virginia. Modified from Warren and others, 1965

Bauxite was discovered at the Cold Spring Kaolin Mine in Augusta County in 1926.

Other mines in Augusta County include the Cold Spring mine, also known as the Chalk Mine. In this area, iron and kaolin were the primary commodities or interest during early operations in the late 1800s (Upchurch, 1998). By 1912, two large test pits were dug southwest of the original iron mining site into the clayey residuum sourced from underlying Tomstown Dolomite and Antietem quartzite. Bauxite was identified at this site in 1926, with samples later analyzed to contain between 29.8 - 39 percent aluminum oxide (Sweet, 1995). The mine was operated until 1951, although less than a carload of bauxite was extracted (Warren and others, 1965).

Minor amounts of bauxite have also been discovered just to the south of Cold Spring Mine at Mine Bank Mine (also known as the old Pulaski mine). Here, manganese was the commodity of interest, although bauxite was discovered within the clay residuum overlying the Antietam quartzite (Knechtel, 1943).

Botetourt CountyNortheast of Roanoke, the Houston Mines were built following the discovery of manganese. Two large open cuts into clayey residuum above the Shady dolomite were dug. Bauxite was also identified here in 1915, making this the first bauxite deposit discovered in Virginia (Warren and others, 1965; Stose and others, 1919). Large masses of bauxite (up to 40 pounds) were observed by Stose and others (1919) with gibbsite-filled cavities. In total, 8 carloads of bauxite were removed from the Houston Mines during 1915 (Stose and others, 1919).

Selected References:

Clarke, O.M., Jr., 1988, Virginia Bauxite Mines - Photographs and prospecting the Virginia bauxite deposits, Spottswood District, 1942: DGMR unpublished report and correspondence in Economic Geology Files.

Dietrich, R.V., 1990, Minerals of Virginia. Department of Mines, Minerals, and Energy, Division of Mineral Resources, Charlottesville, VA.

Fortier, S.M., Nassar, N.T., Lederer, G.W., Brainard, J., Gambogi, J., and McCullough, E.A., 2018, Draft Critical Mineral List - Summary of Methodology and Background Information - U.S. Geological Survey Technical Input Document in Response to Secretarial Order No. 3359: U.S. Geological Survey Open-File Report 2018-1021, 15 p.

Hofstra, A.H., and Kreiner, D.C., 2020, Systems-Deposits-Commodities-Critical Minerals Table for the Earth Mapping Resources Initiative: U.S. Geological Survey Open-File Report 2020-1042.

Knechtel, M.M., 1943, Manganese deposits of the Lyndhurst-Vesuvius district, Augusta and Rockbridge counties, Virginia: U. S. Geol. Survey Bull. 940-F, p. 163-198.

Stose, G. W., Miser, H. D., Katz, F.J., and Hewett, D.F., 1919, Manganese Deposits of West Foot of the Blue Ridge, Virginia: Virginia Geological Survey Bulletin 17.

Sweet, P.C., 1995, Waste Material Resources in Virginia, in Tabilio, M. and Dupras, D.L., eds., 1995, 29th Forum on the Geology of Industrial Minerals: Proceedings; California Department of Conservation, Division of Mines and Geology Special Publication 110, p. 29-37.

Thoenen, J.R., and Burchard, E.F., 1941, Bauxite resources of the United States: U.S. Bureau of Mines Report of Investigations 3598, p. 24-39.

Upchurch, M.L., 1998. The Cold Spring and Related Clay Deposits along the Western Slope of the Central Blue Ridge in Virginia, Virginia Minerals, volume 44, No. 1.

Warren, W.W., Bridge, J., and Overstreet, E.F., 1965. Bauxite deposits of Virginia: USGS Bulletin 1199-A.

.jpg)